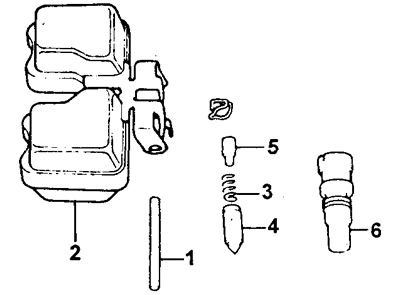

A) evaluate the wear of the float shaft (1);

b) evaluate the wear of the float elements (2);

V) evaluate the condition of the spring (3);

G) assess wear and damage to needle valve components (4, 5);

d) check filter condition (6).

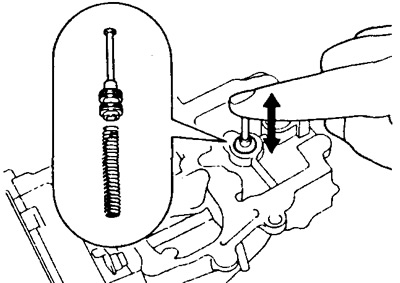

2. Check the operation of the economizer drive piston, making sure it moves freely.

3. Check the operation of the economizer valve ("opening - closing").

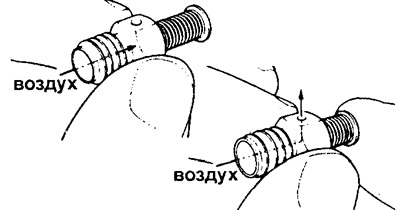

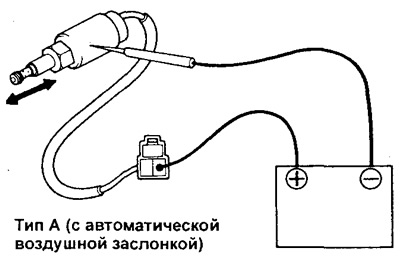

4. Check primary chamber fuel cut off solenoid valve

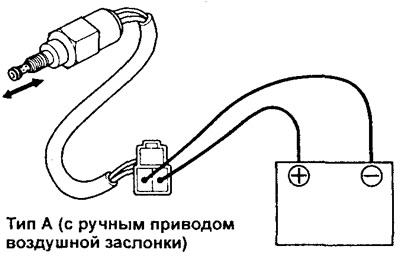

(Type A (with automatic air damper))

A) Connect the valve leads to the battery terminals.

b) When connecting and disconnecting valves to the power supply, you should hear "click".

If it doesn't, replace the valve.

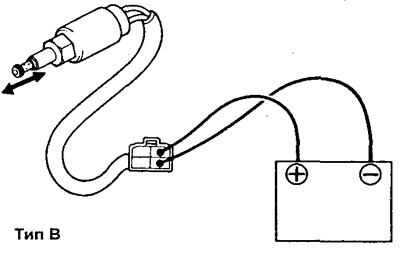

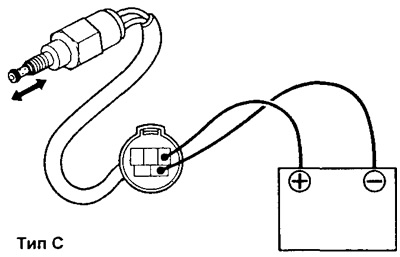

Similarly, check the operation of other types of fuel shutoff solenoid valves, paying attention to the connector terminals to which the battery wires should be connected.

|  |

5. (Engines (2Y-C (U) and 3Y-C (U)) Check the operation of the secondary chamber fuel shutoff solenoid valve.

A) Connect the valve leads to the battery terminals.

b) Must be bugged "click" when connecting and disconnecting the valve to the power supply.

If not, replace the valve.

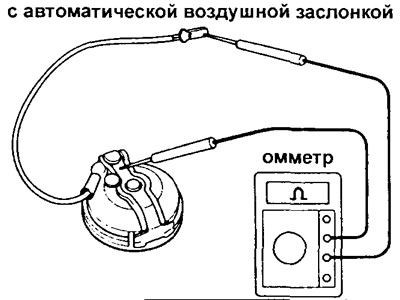

6. (Carburetor with automatic choke)

Check air damper heater (spring housing).

Using an ohmmeter, measure the resistance across the case leads.

Resistance value at 20°C (cold engine) is for engines:

- 2Y-C (U) and 3Y-C (U) — 23-25 Ohm

- for the rest - 17-19 ohms

If the resistance is out of range, replace the entire assembly.

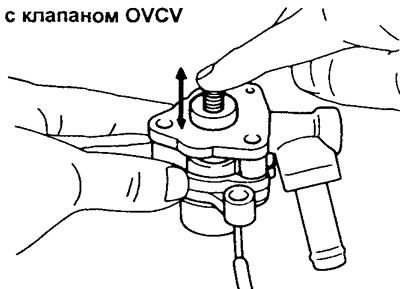

7. (Carburetor with float chamber imbalance valve (OVCV))

A) Check the OVCV valve by checking the condition of the valve and its seat, as well as the smoothness and freedom of movement of the valve guide.

b) Using an ohmmeter, measure the resistance between the valve output terminal and the valve body.

- Resistance value (cold engine) - 63-73 Ohm

If the resistance is out of range, replace the OVCV valve.

V) Connect the valve terminal and valve body to the battery terminals and by moving the valve guide stem, make sure that it does not return to its original position.

If not, replace the OVCV valve.