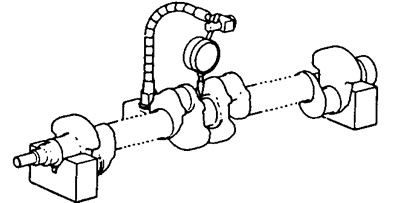

A) Lay the shaft on the prisms.

b) Use a dial indicator to measure the runout of the crankshaft on the middle neck.

- Maximum runout - 0.06 mm

If the runout exceeds the maximum allowable value, replace the crankshaft.

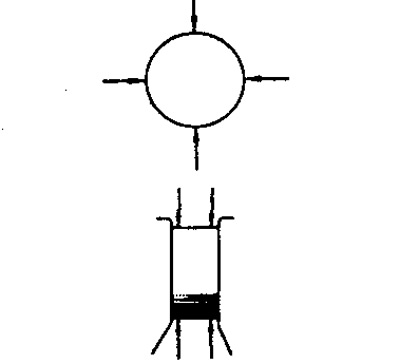

2. Check the connecting rod and main journals.

A) Using a micrometer, measure the diameter of the main and connecting rod journals.

Main journal diameter:

- Nominal size - 61.985-62.000 mm

- 1st repair size - 61.745-61.755 mm

- 2nd repair size - 61.495- 61.505 mm

Crankpin Diameter:

Engine 2L

- Nominal size - 52.988 - 53.000 mm

- 1st repair size - 52.745-52.755 mm

- 2nd repair size - 52.495- 52.505 mm

Engine 3L

- Nominal size - 54.988 - 55.000 mm

- 1st repair size - 54.745 - 54.755 mm

- 2nd repair size - 54.495 - 54.505 mm

If the diameter does not correspond to the specified limits, then check the clearances in the main and connecting rod bearings.

Regrind or replace crankshaft if necessary.

b) Check each main journal and connecting rod journal for taper and out-of-roundness.

- Maximum allowable taper and out-of-roundness: 0.02 mm

If the taper or out-of-roundness exceeds the maximum allowable value, grind or replace the crankshaft.

3. If necessary, grind and honing the main bearing journals and/or connecting rod journals.

Establish loose leaves of radical and rod bearings corresponding to the repair size.