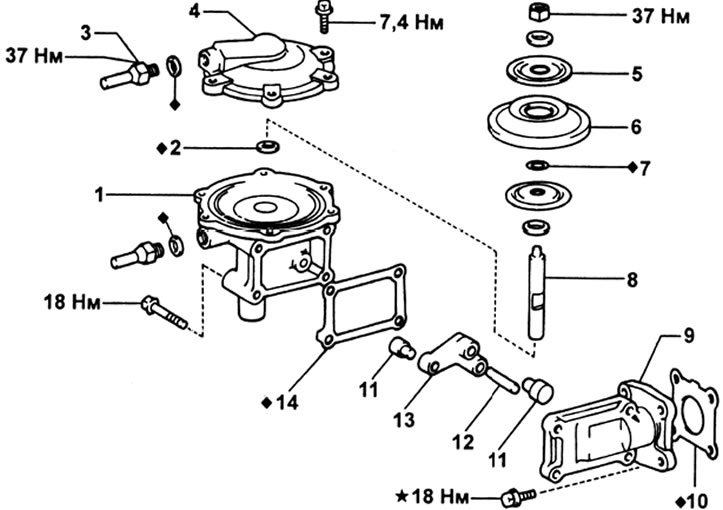

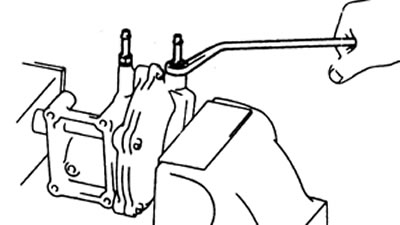

Pneumatic drive. 1 - diaphragm mechanism housing, 2 - stuffing box, 3 • fitting, 4 - cover, 5 - plate, 6 - diaphragm, 7 - end gasket, 8 - diaphragm rod, 9 - gasket, 10 - actuator housing, 11 - support, 12 - lever axis, 13 - all-wheel drive lever, 14 - gasket.

Disassembly

1. Remove the diaphragm mechanism.

2. Remove the 4WD lever from the axle in the actuator housing. Use a drift and hammer to knock out the supports from the lever.

3. Checking the diaphragm mechanism.

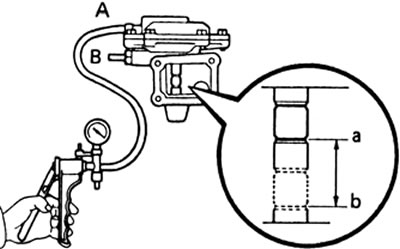

A) Create a vacuum of at least 400 mm Hg. (53.3 kPa) on the fitting "A" or "IN" and make sure that the diaphragm rod moves.

b) Check full stroke (between points "A" And "b").

Permissible value - 21 mm

V) At a rarefaction of at least 400 mm Hg. (53.3 kPa) check for leaks in the diaphragm mechanism (no fluctuation of the pressure gauge pointer on the pump).

4. Remove fittings and gaskets from cover and diaphragm housing.

5. Remove the six bolts, then remove the diaphragm cover and remove the diaphragm rod.

6. Remove the nut and parts from the diaphragm stem.

Assembly

1. Replacing the diaphragm stem seal (if necessary).

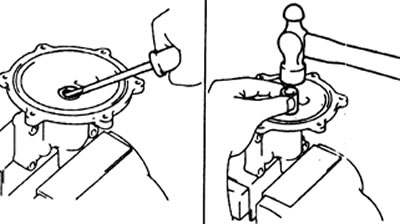

A) Using a flat blade screwdriver, pry the oil seal out of the diaphragm case.

b) Using a mandrel and a hammer, press in a new oil seal.

V) Apply grease to the seal lip.

2. Install the parts on the diaphragm rod and tighten the fastening nut.

Tightening torque - 37 N.m

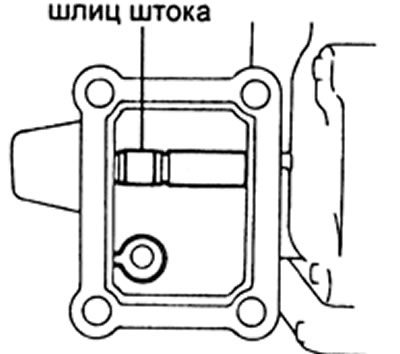

3. Install the diaphragm stem into the diaphragm mechanism housing so that the slot on the stem is in the exposed portion of the housing.

4. Install the cover on the diaphragm case and tighten the six mounting bolts.

Tightening torque - 7.4 N.m

5. Install fittings with new gaskets.

Tightening torque - 37 N.m

6. Press two supports into the all-wheel drive lever. Install the lever on the axle.

7. Install diaphragm mechanism.