Attention:

- Do not bend, twist or turn the belt inside out.

- Do not allow the belt to come into contact with oil, water or steam.

- When installing or removing the camshaft pulley mounting bolt, the belt must not be under tension.

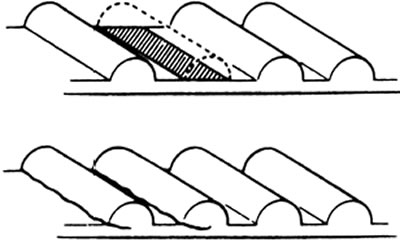

If any of the defects shown in the figures are found, then perform the following checks:

A) In case of premature rupture:

- check the correct installation of the belt.

- check for damage and correct installation of the belt cover gasket.

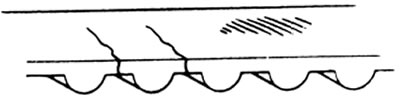

b) If the belt teeth are cracked or damaged, check the camshaft mounting.

V) If there are cracks or visible signs of wear on the back of the belt, check the surface of the tensioner pulley and the water pump pulley.

G) If wear or damage is observed on only one side of the belt, check the belt guide and pulley alignment.

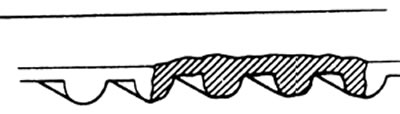

d) If there is noticeable wear on the belt teeth, then check the belt cover for damage, and then check that the gasket is installed correctly. Check for foreign material on the pulley teeth.

If necessary, replace the belt.

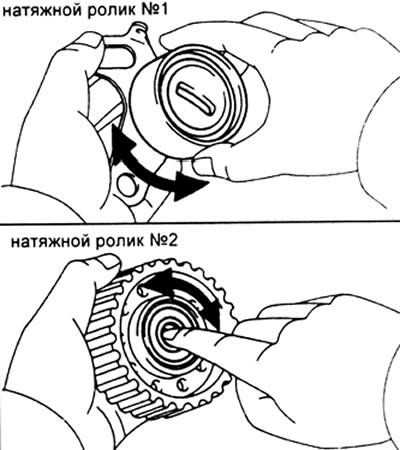

2. Check up smoothness of rotation of a tension roller. If necessary, replace the tension roller.

3. (Series L) Tension spring check.

A) Measure the length of the tension spring.

Loose - 44.4 - 45.4 mm If the free length of the spring is not within the specified limits, replace the tension spring.

b) Measure the tension force of the spring to the specified length.

Tensile force - 5.42 - 5.98 kg (with a length of 52.1 mm)

If the tensile force does not meet the specified values, replace the tension spring.

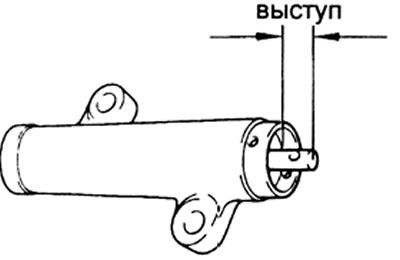

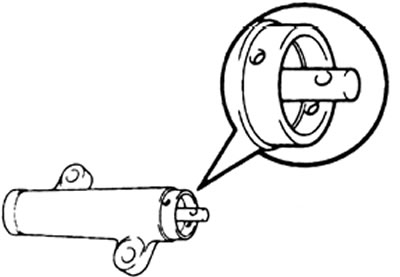

4. (Engine 1KZ-T) Tensioner check.

A) Check for oil leaks from the tensioner.

Note: A small amount of leakage is allowed through the tensioner plunger seal.

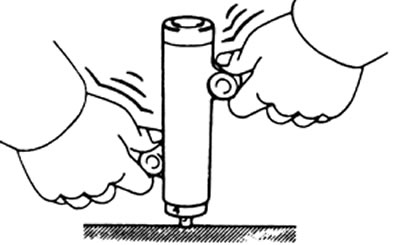

b) Press the tensioner plunger onto a hard surface (workbench or wall): The plunger must not move. If the plunger moves, replace the tensioner.

V) Measure the protrusion of the plunger from the body. If the protrusion is out of range, replace the tensioner.

Plunger protrusion - 9.0-9.8 mm