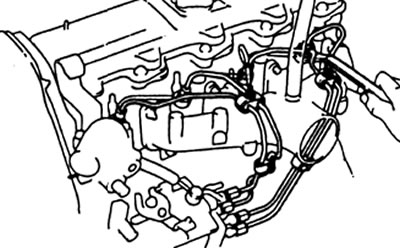

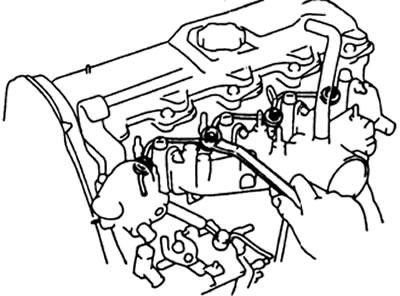

Removing nozzles

1. (Series L) Remove the glow plug busbar.

2. (1KZ-T) Remove the intake duct.

2. Removing the high pressure pipes.

A) Loosen the four tube nuts.

b) Remove the top two clamps, the four high pressure tubes and the two bottom clamps.

3. Removing the drain tube.

A) Disconnect the fuel hose from the drain tube.

b) Remove four nuts, drain tube and four sealing washers.

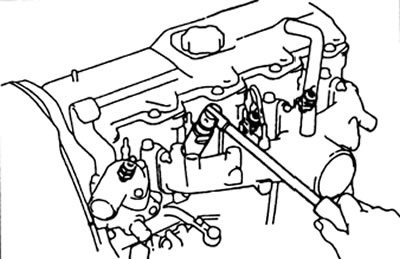

4. Turn out four nozzles.

Note: Arrange the injectors in the order in which they were removed.

Checking the injectors

1. Checking the pressure of the beginning of the lifting of the needle of the atomizer.

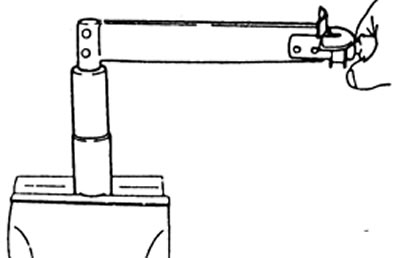

A) Fix the nozzle on the stand. Attention: do not put your fingers under the spray nozzle.

b) Pump the nozzle until a steady spray appears.

V) Make several movements with the handle of the device as often as possible to knock off carbon deposits from the nozzle opening.

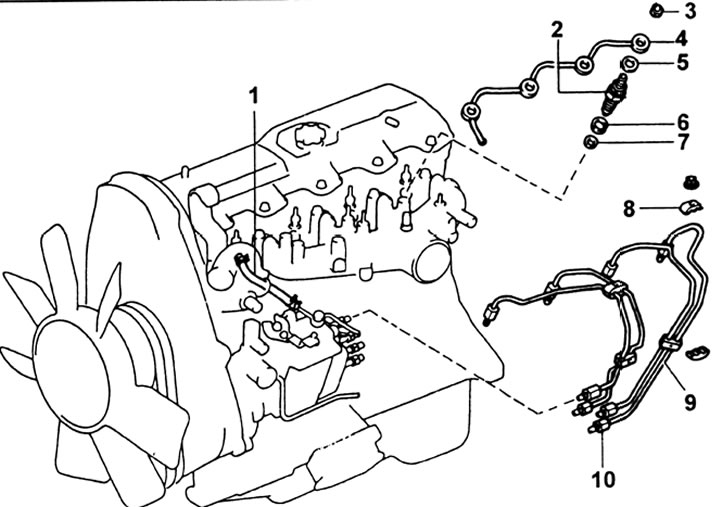

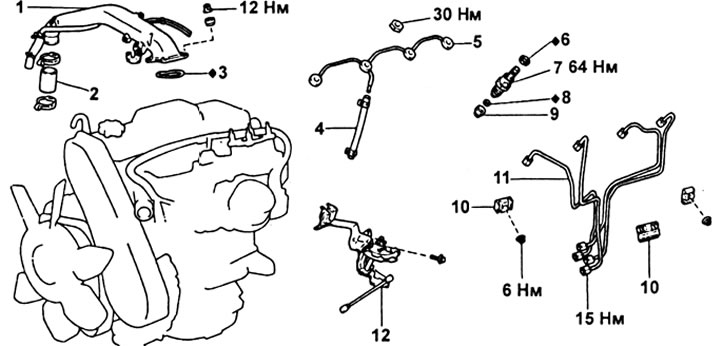

Removing nozzles (L-series): 1 - fuel hose, 2 - nozzle M.Z. 64 N.m, 3 - nut M. 3. 29 N.m, 4 - drain tube, 5, 7 - gasket, 6 - sealing washer, 8 - clamp, 9 - high pressure pipes, 10 - tube nuts M. 3. 25 N·m.

Removing nozzles (KZ-series): 1 - air intake duct, 2 - hose, 3 - gasket, 4 - fuel return hose, 5 - drain tube, 6 - sealing washer, 7 - nozzle, 8 - sealing washer, 9 - nozzle seat, 10 - clamp, 11 - fuel high-pressure pipes, 12 - bracket and drive rod of the injection pump lever.

G) Lowering the handle of the stand with a frequency of one stroke per second, count the pressure at the beginning of the needle lift.

Series L:

- when adjusting - 151-159 bar

- when checking - 145-155 bar

KZ Series:

- when adjusting - 148 - 156 bar

- when checking - 147-156 bar

If the pressure of the beginning of the lifting of the needle does not correspond to the specified value, disassemble the nozzle and replace the adjusting washer located under the spring. Washers are available in thicknesses from 0.9 to 1.95 mm in increments of 0.025 mm

Note: A change in the thickness of the shim by 0.025 mm causes a change in injection pressure of approximately 3.5 bar (L-series) or 5.0 bar (KZ-series). It is advisable to install one adjusting washer.

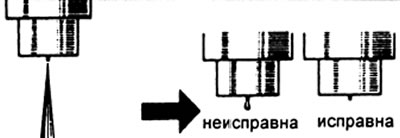

d) After the end of the injection, there should be no fuel leakage.

2. Checking the tightness of the needle. Maintain the pressure in front of the nozzle 10-20 bar below the pressure of the beginning of the needle lift - within 10 seconds, not a drop of fuel should appear from the atomizer and from under the nozzle coupling nut.

If drops appear, replace the atomizer or sort out the nozzle.

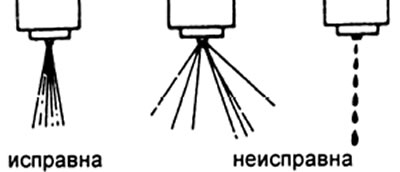

3. Checking the spray pattern.

A) Pump the stand handle at a frequency of one stroke per second.

b) The fuel jet must be symmetrical, not have pronounced drops and separate jets.

Disassembly of nozzles

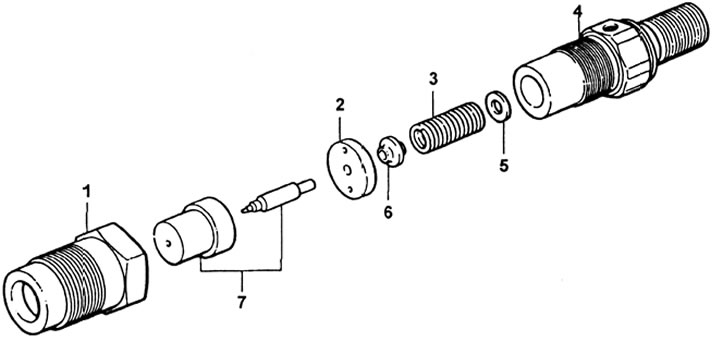

1. Loosen the nozzle union nut. Caution: Care must be taken when disassembling an injector, never disassemble several injectors at the same time.

2. Remove the atomizer, spacer, spring and shim.

Checking the condition of the injectors

1. Cleaning the nozzle.

A) Use a wooden spatula and a brass brush to clean the nozzles. Wash parts in clean diesel fuel.

Note: Do not touch the surfaces of the precision pairs with your fingers.

b) Using a wooden rod, remove the carbon deposits that have settled on the nozzle needle.

V) Using a brass brush, remove carbon deposits from the end of the atomizer

G) Check the needle seat for burnout or corrosion.

d) Check the atomizer needle for damage or corrosion. If any of the indicated defects are found, replace the atomizer.

2. Check the condition of the nozzle sprayer.

A) Flush the atomizer in clean diesel fuel.

Note: Do not touch the surfaces of the precision pairs with your fingers.

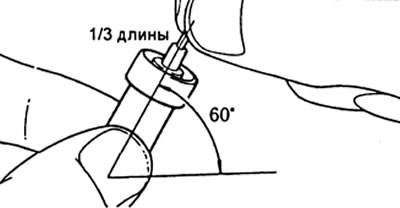

b) Tilt the nebulizer body approximately 60°to the vertical and extend the needle approximately one third of its length.

V) Release the needle, it should drop smoothly under its own weight.

G) Repeat the test several times, turning the needle slightly before each test.

If the needle does not drop, replace the atomizer.

Assembly of nozzles

1. Install in the body: shim, spring, pushrod, spacer and atomizer. Tighten the nozzle nut.

Torque - 37 Nm

Attention: Exceeding the tightening torque may cause deformation of the nozzle, sticking of the needle and other malfunctions.

2. Check the needle lift start pressure and spray quality.

Nozzle disassembly: 1 - nozzle coupling nut, 2 - spacer, 3 - spring, 4 - nozzle body, 5 - adjusting washer, 6 - pusher, 7 - atomizer.

Installation of nozzles

1. Place new washers and nozzle seats in the head. Tighten the injectors to 64 Nm.

Attention: Exceeding the tightening torque may cause deformation of the nozzle, sticking of the needle and other malfunctions.

2. Installation of the drain tube.

A) Install four new gaskets and tube. Tighten nuts to 29 Nm.

b) Connect the fuel return line.

3. Installation of high pressure pipes,

A) Attach the bottom clips to the intake manifold.

b) Install four high pressure pipes. Tightening torque for tube nuts 25 N.m (L-series) or 15N-m (KZ-series).

V) Secure the tubes with clamps.

4. (Only L) Install the glow plug current bar.

5. (Only 1KZ-T) Install the injection pump lever drive bracket and rod, intake air duct

6. Start the engine and check for fuel leaks.