Clutch wear

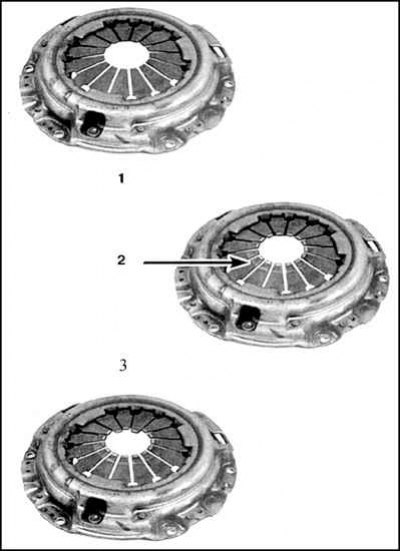

1. Normal wear of petals; 2. Increased wear of the petals; 3. Broken or deformed spring petals

Attention! Remove dust from the wear of the linings with a special cleaner. The use of gasoline or thinner is not allowed.

Removing

When describing the procedures, it is assumed that the work is carried out without removing the engine.

1. Remove the master cylinder.

2. Jack up the engine and remove the transmission. If the engine is supported from below, then keep in mind that the oil receiver is located near the sump and if the sump is deformed, oil access to the engine may be blocked.

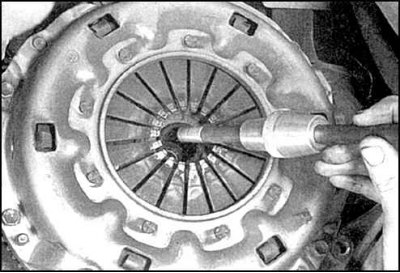

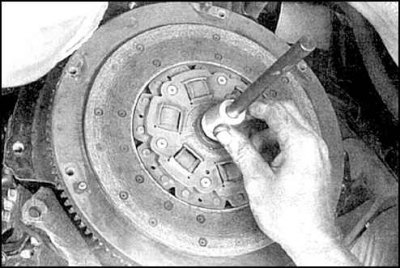

3. Fix the clutch by inserting the mandrel.

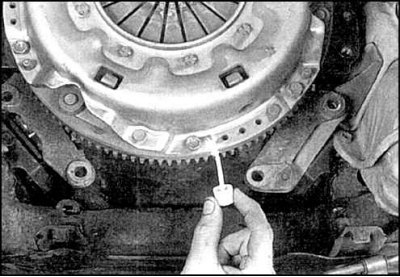

4. Find match marks (letters X or O), if missing, mark the position of the clutch on the flywheel.

5. Gradually, for 1/2 turn per reception, evenly loosen 6 bolts, unscrew the bolts and remove the clutch.

Examination

As a rule, only the friction disc needs to be replaced. However, the condition of all parts should be inspected.

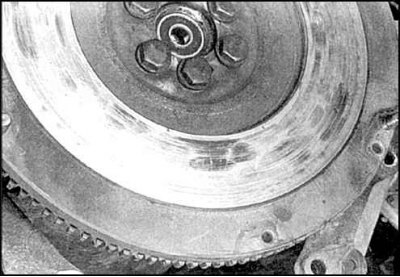

1. Check the condition of the flywheel.

2. It is recommended to remove the flywheel and grind regardless of the surface condition.

3. Check the condition of the guide bearing.

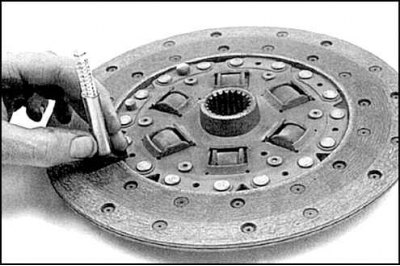

4. Check the surface condition of the friction linings, measure the distance to the disc rivet heads, which should be at least 0.8 mm.

5. Check the condition of the springs, loose rivets, and other signs of damage.

6. It is recommended to replace the drive regardless of its condition.

7. Together with the friction disc, the release bearing also usually changes.

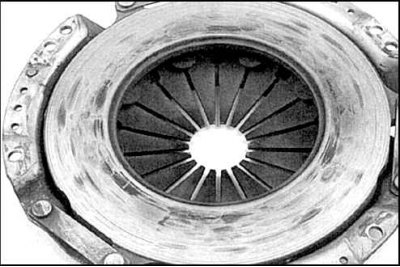

8. Check the condition of the pressure plate surface.

9. Check the condition of the diaphragm spring and spring petals (see fig. Clutch wear).

10. Minor defects in the disc can be sanded with sandpaper; in case of significant defects, replace the clutch.

Installation

1. Thoroughly clean the flywheel and clutch.

2. Install the clutch, aligning the marks, and tighten the bolts by hand.

3. Center the disc with a mandrel that should go into the pilot bearing, gradually and evenly, in a cross pattern, tighten the clutch bolts.

4. Lubricate the release bearing groove, the friction surfaces of the fork and the splines of the gearbox input shaft with refractory grease.

5. Install the bearing.

6. Install transmission.

7. Tighten all fasteners to the specified torque.