Installation

1. Position the block so that the bottom is facing up.

2. Turn out bolts of covers, get covers and lay them out in the order of their installation.

3. Remove the old liners from the covers and cylinder block and wipe the covers and beds clean.

4. Clean the outer surface of the new oil-grooved main bearings, and carefully insert them into the cylinder block bed.

5. Insert the corresponding reciprocal inserts into the covers, aligning the protrusions with the selections.

6. Do not lubricate inserts.

Clearance check

1. Establish persistent half rings in deepenings of the block of cylinders. On 2F and 3F-E engines, the half rings are installed next to the 3rd bearing support, on 1FZ-FE engines - next to the 4th bearing support.

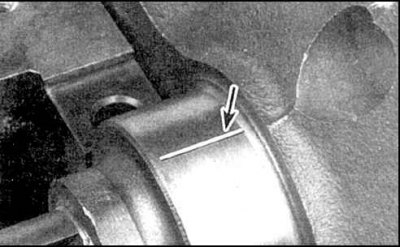

2. Install the crankshaft and measure the clearances in the main bearings. To do this, put a piece of calibration wire (arrow) on each main journal of the crankshaft parallel to its axis.

3. Clean the surfaces of the liners in the covers, install the covers and tighten the bolts in three steps to the specified torque, starting from the center and moving to the periphery.

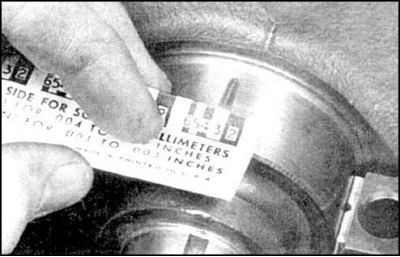

4. Loosen the bolts and carefully lift the covers, compare the thickness of each of the crushed wires with the scale on the package and determine the gap. Rotation of the crankshaft during measurements is not allowed.

5. If the gap is not correct, then the reason may be the wrong selection of the size group of the liners.

6. Make sure there is no dirt or oil between the bearings and the cover surfaces when measuring. If the width of the crushed wire at the ends is very different, then the crankshaft main journal has a taper.

7. Remove the remnants of the wire from the necks and remove the crankshaft.

8. Lubricate the main bearing shells and the end surface of the thrust main bearing with molybdenum grease. Install in the cylinder block of the rear section (detachable) oil seal and rear main bearing cap.

Final crankshaft installation

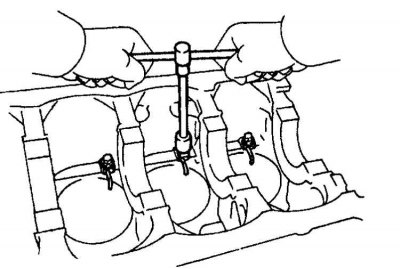

1. On the 1FZ-FE engine, install oil nozzles and control valves in the cylinder block.

2. Make sure the crankshaft journals are clean, then install it in the cylinder block. Clean the surfaces of the liners in the caps and apply a thin layer of lubricant to each of them.

3. Replace the covers in their original positions with the arrows pointing towards the front of the engine.

4. Wrap bolts of covers of radical bearings.

5. Tighten all cap bolts except for the thrust main bearing cap to the specified torque. Tighten the bolts in 3 stages, starting from the middle part and moving towards the periphery.

6. Tighten the thrust main bearing cap bolts with a torque of 1.0–1.2 Nm.

7. Lightly tap the crankshaft with a lead or brass hammer to align the thrust surfaces of the main bearings and the crankshaft.

8. Loosen the cover bolts and tighten again with the specified torque, starting from the middle part and moving towards the periphery.

9. On vehicles with automatic transmission, replace the crankshaft guide bearing.

10. Check the freedom of rotation of the crankshaft.

11. Check crankshaft end play (see subsection 3.3.7.4). The play must be correct if new bearings are installed and the thrust washers are not worn.

12. On vehicles with a one-piece rear oil seal, install a new rear oil seal.