- A) Install the pin in the bearing holder.

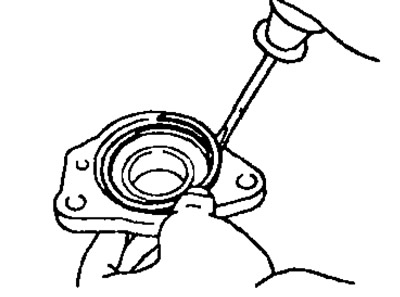

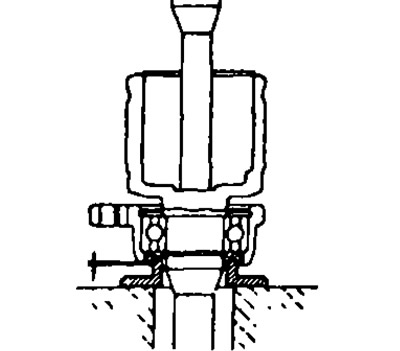

- b) Using the special tool and a press, install the new bearing into the bearing holder.

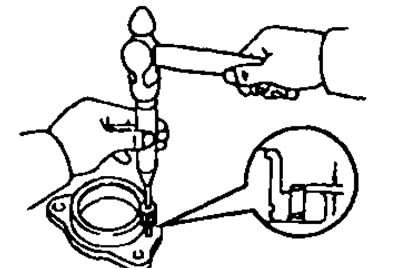

- V) Using a screwdriver, install a new circlip.

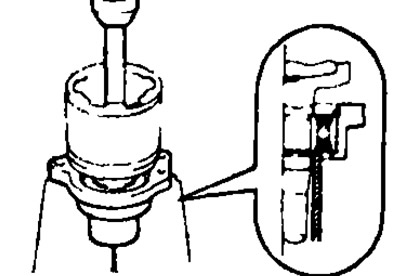

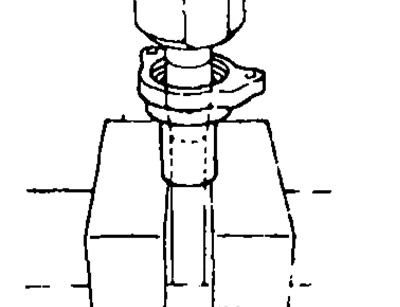

- G) Using the special tool and a press, install the bearing holder assembly onto the center drive shaft.

- d) Using the special tool, install a new circlip.

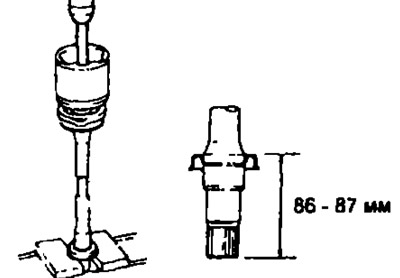

- e) Using the special tool and a press, install a new boot.

Note: The clearance shown in the figure must remain between the dust boot and the bearing.

2. (3S-GE, 3S-FE and 4S-FE) Install the new boot as shown in the illustration.

3. Temporarily install hinge covers with new clamps on the shaft.

Note: Wrap electrical tape around the splines of the drive shaft before installing the boot to prevent damage to the boot.

(For the right drive shaft of models with engines 2C, 4A-FE) Temporarily install the damper and a new damper clamp. Standard distance:

- 4A-FE: 431.6±5.0mm

- 2С: 351.5±5.0 mm

4. (3S-GE) Install the inner hinge.

- A) Using the special tool, install a new circlip.

- b) Align the alignment marks and install the inner race on the central drive shaft using a copper rod and a hammer.

Caution: Be careful not to damage the inner race.

- V) Using the special tool, install a new circlip.

- G) Align the alignment marks and install the separator on the inner race.

Attention: install the separator with a smaller diameter to the outer hinge.

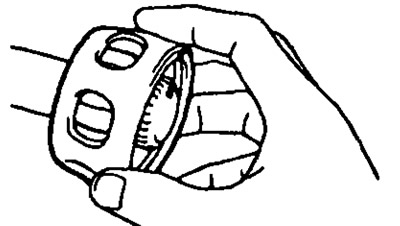

- d) Set six balls.

Note: Apply lubricant to the balls.

(3S-FE, 2C, 4A-FE and 4S-FE) Install the triple joint.

- A) (3S-FE and 4S-FE) Using the special tool, install a new circlip.

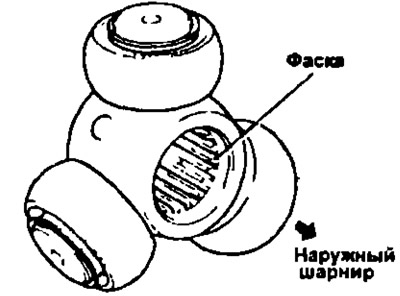

- b) Rotate the triple joint with the splined chamfer towards the outer joint.

- V) Align the alignment marks made before disassembly.

- G) Using a copper rod and a hammer, press the triple joint onto the drive shaft.

Attention: do not drop the hinge.

- d) Using the special tool, install a new circlip.

5. Install the cover on the outer hinge, having previously laid grease in the hinge and the boot.

Note: When assembling, use a lubricant designed for hinges only. Amount of lubricant:

- 3S-GE: 100-120g

- 3S-FE, 2C and 4A-FE: 120-130g

6. Install the inner joint race on the drive shaft.

- A) Apply grease to the inner joint race and boot.

Note: Use only grease designed for hinges when assembling. Amount of lubricant:

- 3S-GE: 100-120g

- 3S-FE, 2C, 4A-FE and 4S-FE: 180-190g

- b) Align the alignment marks and install the inner joint race on the drive shaft.

- V) (3S-GE) Install a new retaining ring.

- G) Install the cover on the inner hinge race.

7. Establish collars of covers. (For the right drive shaft of models with engines 2C, 4A-FE) Fix the damper clamp.

- A) Check that the cover is in the groove of the shaft.

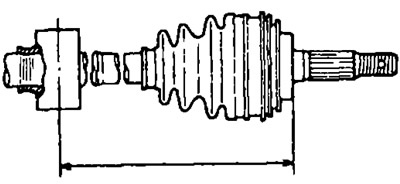

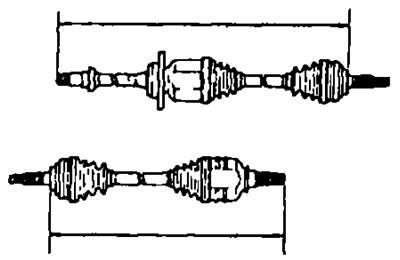

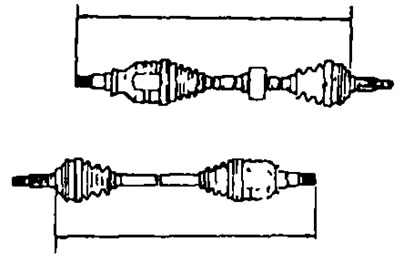

- b) Check that the boot has not been stretched or compressed at the standard length of the drive shaft.

Standard drive shaft length:

- Left side for models with engine:

- 3S-GE: 554.2±5.0mm

- 3S-FE: 558.2±5.0mm

- 2С: 548.5±5.0 mm

- 4A-FE: 541.3±5.0mm

- Right side for models with engine:

- 3S-GE: 841.8±5.0mm

- 3S-FE: 844.6±5.0mm

- 2C: 859.9±5.0 mm

- 4A-FE: 855.8±5.0mm

- V) Fasten the clamps.