Turbocharger operation

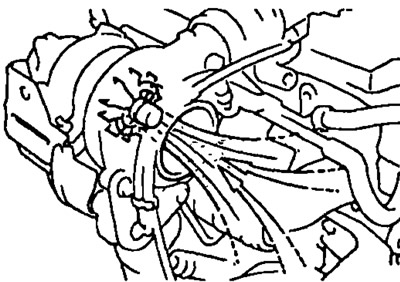

The exhaust gases, which are still at a rather high temperature, are brought to the turbine wheel, causing the wheel to rotate. When the turbine rotates, the gases expand and transfer to the unit shaft the excess power spent on compressing the air in the compressor located on a common shaft with the turbine. The rotational speed of the turbocharger shaft varies in the range of 20,000-115,000 rpm, which is accompanied by a characteristic "whistling" turbines.

Gas bypass valve past the turbine

If the pressure of the air supplied by the compressor exceeds the allowable (engine reliability conditions), exhaust gases are bypassed past the turbine by a special valve with an autonomous drive. The drive is a diaphragm driven by the pressure of the intake air. In this way, feedback control of the boost pressure is carried out.

Warnings

1. Do not turn off the engine immediately after completing a trip. Let the engine idle for 20-120 seconds to cool the turbine. This will significantly extend the life of the turbocharger. (Install a turbo timer if possible).

2. Avoid prolonged operation of the engine at high speeds and sudden acceleration when the engine is cold.

3. If the turbocharger fails prematurely, check:

- Engine oil level and quality.

- Working conditions of the turbocharger.

- Pipelines supplying oil to the turbocharger

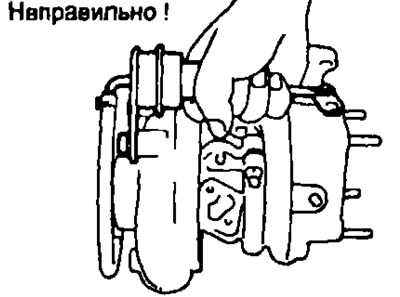

4. Be careful when dismantling and installing the turbocharger. Do not carry the unit by the bypass valve actuator rod.

5. After dismantling the turbocharger, close the inlet and outlet pipes and oil holes with plastic plugs.

6. Before installing the turbocharger, flush the oil supply pipe

7. Before installation, clean the mating surfaces of the turbocharger and oil pipes.

8. When replacing fasteners, install only original products.

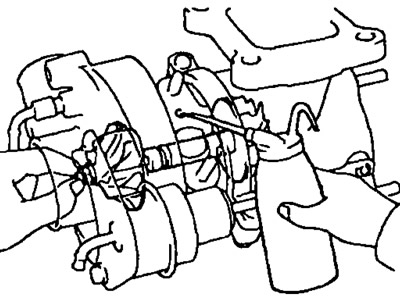

9. After installing the compressor, pour 20 cm into the bearing housing3 engine oil, turn the compressor shaft by hand.

10. After replacing the compressor, crank the engine with a starter for 20-30 seconds (without engine start) to fill the lubrication system or let the engine idle for at least one minute.

11. Do not operate the engine with the air filter removed. Otherwise, the compressor wheel will fail very quickly.