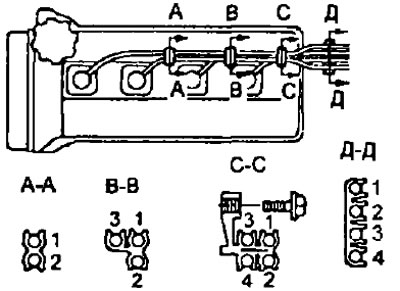

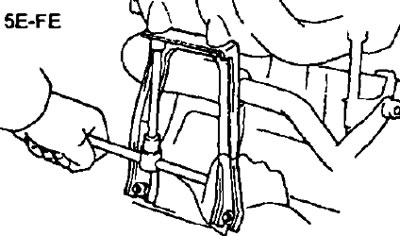

Dismantling of a head of the block of cylinders (5E-FE) 1 - air duct; 2 - intake manifold; 3 - gasket; 4 - throttle body; 5 - bracket for the upper part of the intake manifold; 6 - distributor assembly with high-voltage wires; 7 - vacuum hose; 8 - engine lifting bracket No. 2; 9 - cylinder head cover; 10 - gasket; 11 - intake camshaft; 12 - bearing cover No. 4 of the camshaft; 13 - bearing cover No. 3 of the camshaft; 14 - adjusting washer; 15 - pusher; 16 - crackers; 17 - spring plate; 18 - valve spring; 19 - oil scraper cap; 20 - support washer; 21 - valve; 22 - segment plug; 23 - thermostat housing; 24 - coolant bypass hose; 25 - exhaust manifold heat shield; 26 - exhaust manifold. 27 - cover No. 3 of the timing belt; 28 - cylinder head gasket; 29 - engine lift bracket N91; 30 - insulator; 31 - cylinder head; 32 - spacer sleeve; 33 - gasket; 34 - fuel manifold assembly with injectors; 35 - valve guide sleeve; 36 - fuel supply hose; 37 - exhaust camshaft; 38 - stuffing box; 39 - bearing cover No. 1 of the camshaft; 40 - leaf spring of the camshaft gear; 41 - auxiliary gear camshaft; 42 - retaining ring; 43 - spring washer; 44 - plug of the intake camshaft; 45 - bearing cover No. 2 of the camshaft; 46 - gasket; 47 - intake manifold bracket; 48 - oil filler cap; 49 - hose of the crankcase ventilation system; 50 - gasket; 51 - air bypass valve for exhaust; 52 - air bypass valve for exhaust (ACV); 53 - ring seal; 54 - vacuum modulator of the exhaust gas recirculation system; 55 - pipe of the exhaust gas recirculation system, assembly; 56 - exhaust gas recirculation valve; 57 - gasket.

Installing the cylinder head

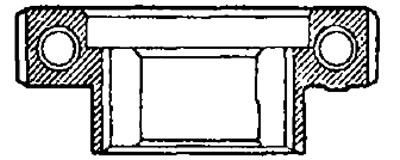

1. Install the cylinder head on the cylinder block by installing a new cylinder head gasket on the block

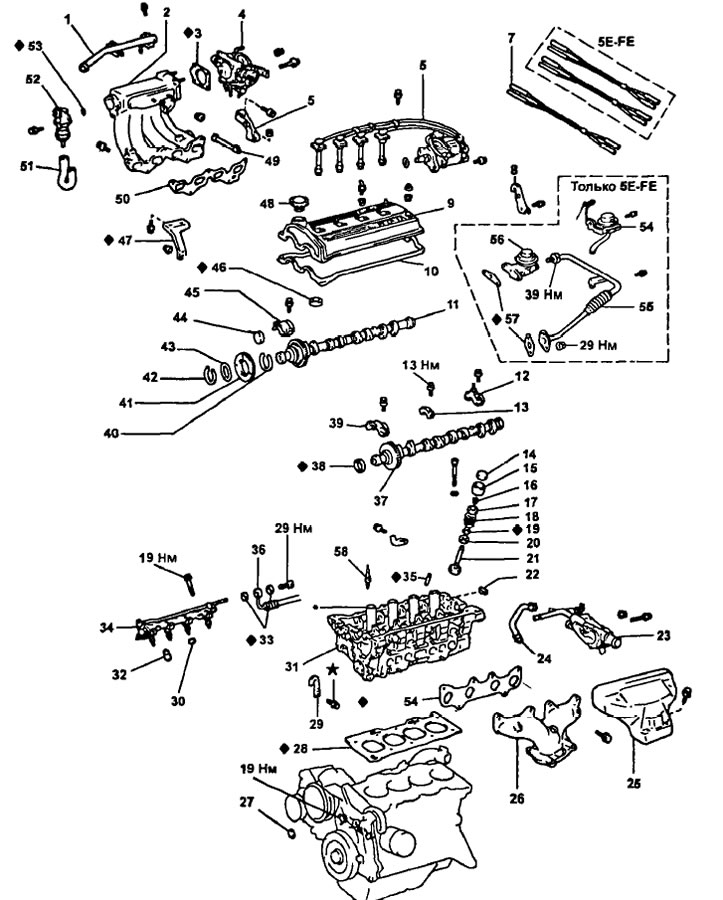

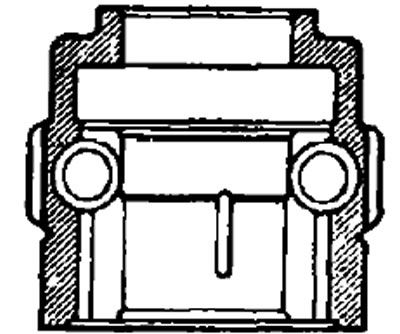

2. Establish bolts of fastening of a head of the block of cylinders.

Note:

- The cylinder head bolts are tightened in the dev stage.

- If any cylinder head bolt is broken or deformed, replace it.

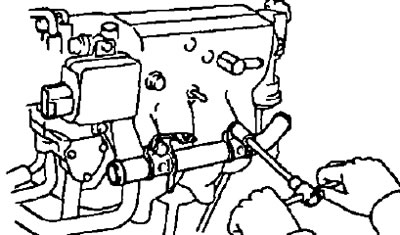

- A) Apply a light coat of engine oil to the threads and under the heads of the mounting bolts.

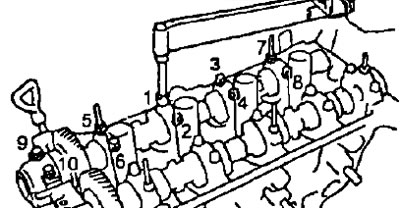

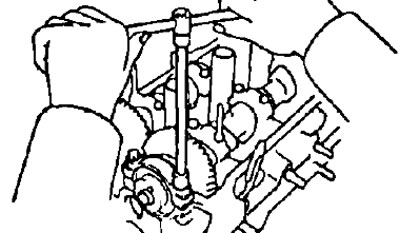

- b) Install and using an 8 mm wrench progressively tighten in several passes (at least 3) block head bolts in the sequence shown in the figure.

- Tightening torque - 44 Nm

Note: bolts (A), marked in the figure are longer than the bolts (IN).

If any bolt is not tightened to the correct torque, replace the bolt.

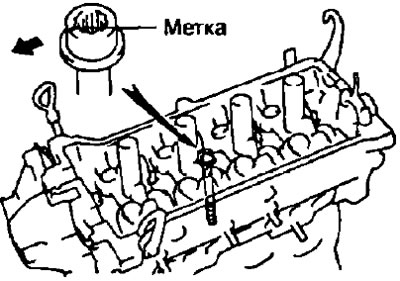

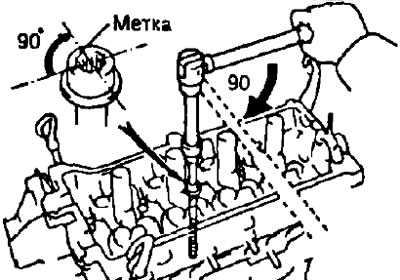

- G) Apply paint marks to the front of the cylinder head bolts.

- d) Tighten the cylinder head bolts 90°.

- e) Check that the inked mark is 90°from its original position.

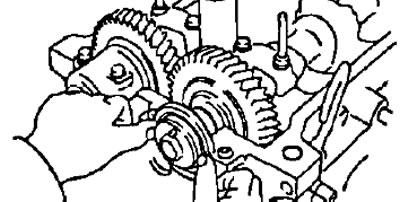

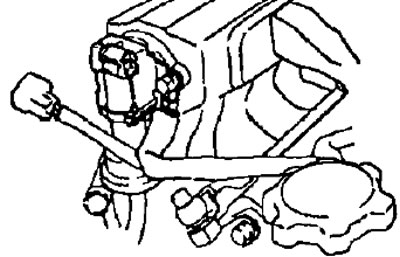

3. Assemble the intake camshaft.

- A) Clamp the hex section of the camshaft in a vise.

Note: Do not damage the camshaft.

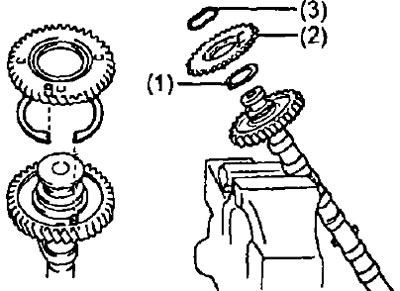

- b) Install the following parts:

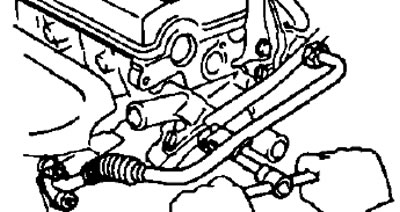

- leaf spring (3) camshaft gears;

- auxiliary gear (2) camshaft drive;

- spring washer (1).

Note: Align the pins on the gears with the ends of the leaf spring (3), as it shown on the picture.

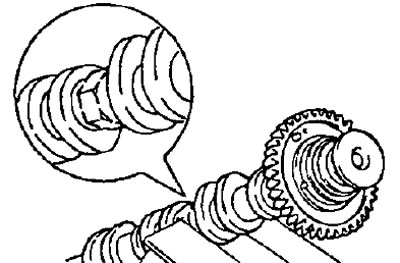

- V) Using pliers, install the retaining ring.

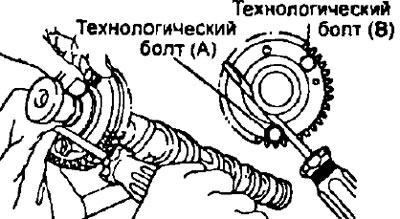

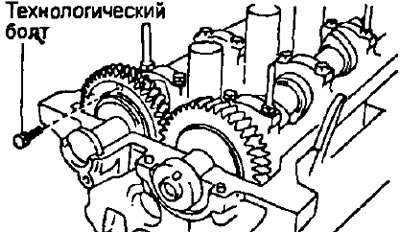

- G) Insert process bolt (A) in the technological hole of the auxiliary gear of the camshaft drive.

- d) Using a screwdriver, align the hole of the camshaft drive main gear and the sub gear by turning the camshaft drive sub gear clockwise; then install the technological bolt (IN).

4. Install the camshafts

Note: when installing camshafts, it must be taken into account that the axial clearance is very small; therefore, the shafts must be laid in the bed of bearings strictly horizontally, without distortions, in order to avoid jamming and / or damage to the shafts.

To avoid this, follow the following sequence of procedures.

- A) Apply a layer of engine oil to the end thrust surfaces of the camshaft.

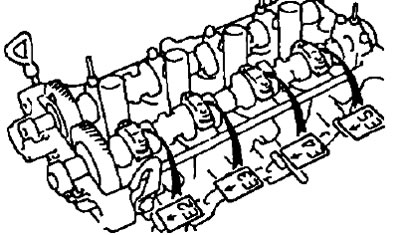

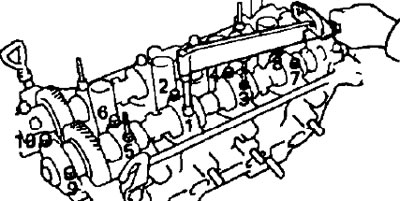

- b) Install the intake camshaft as shown, with the intake camshaft service bolt up and the #3 and #4 cam lugs down.

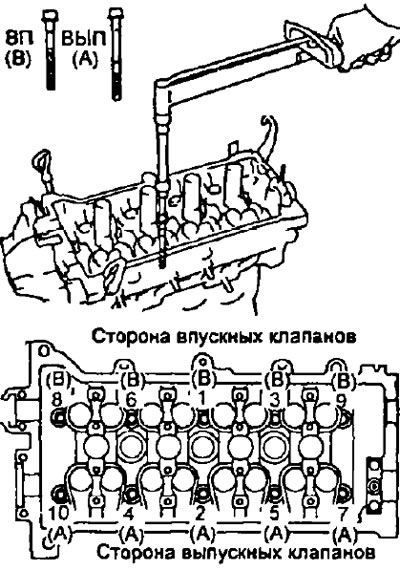

- V) Install the four bearing caps in their respective locations.

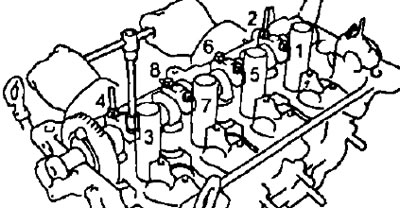

- G) Temporarily tighten the bearing cap bolts by alternately tightening the right and left bolts in the sequence shown in the figure.

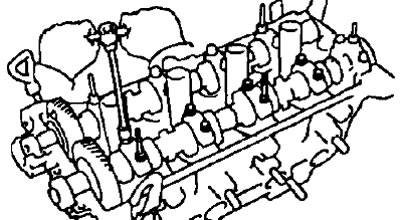

- d) Apply engine oil to the ends of the exhaust camshaft.

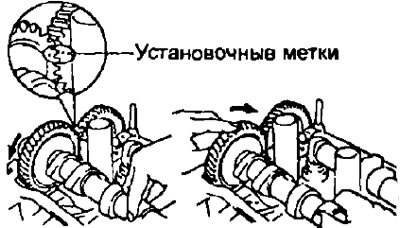

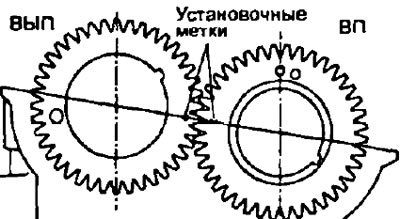

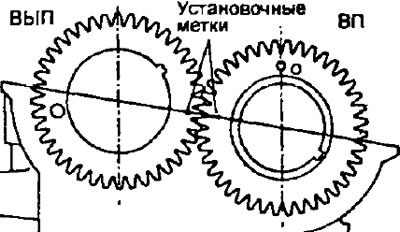

- e) Engage the exhaust and intake camshaft drive gears by aligning the alignment marks on these gears with each other.

- and) Keeping the gears engaged, roll the exhaust camshaft into its journals on the cylinder head.

- h) Push lightly on the exhaust camshaft towards the front of the engine, but do not apply much force.

- And) Install the four exhaust camshaft bearing caps.

- To) Temporarily tighten the bearing cap bolts evenly and alternately.

- l) Turn away a technological bolt.

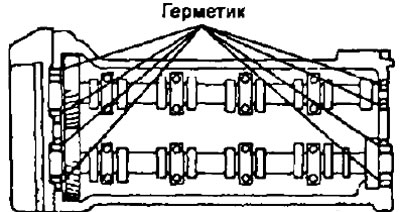

- m) Clean the surface of the N22 bearing cap and apply sealant to the area indicated in the figure.

- n) Install the Ne2 bearing cap, and then check that there is no clearance between the cylinder head and the contact surface of the bearing cap.

- O) Tighten the #2 bearing cap bolts evenly and alternately for a while.

- P) Install the intake camshaft cap.

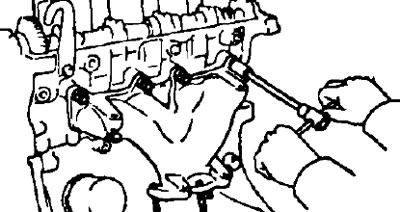

- R) Install and tighten the ten intake camshaft bearing cap bolts alternately and evenly in the sequence shown in the figure.

- Tightening torque - 13 Nm

- With) Apply sealant to the new camshaft seal and install the new seal as deep as possible into the cylinder head.

- T) Clean the surface of the #1 bearing cap and apply sealant to the area indicated in the illustration.

- at) Install bearing cap No. 1, then check for clearance between the cylinder head and the contact surface of the bearing cap

- f) Tighten the #1 bearing cap bolts evenly and alternately for a while

- X) Install and tighten the ten exhaust camshaft bearing cap bolts alternately and evenly in the sequence shown in the figure.

- Tightening torque - 13 Nm

- c) Turn the camshafts and check the alignment of the alignment marks.

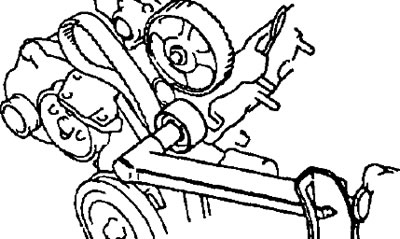

5. Install the camshaft sprocket.

- A) Align the exhaust camshaft locating pin with the pin groove on the sprocket and install the sprocket.

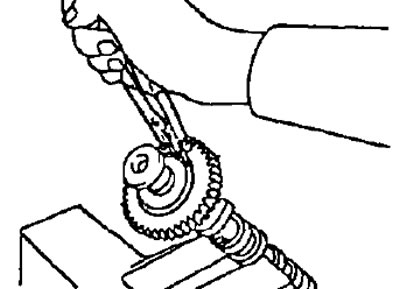

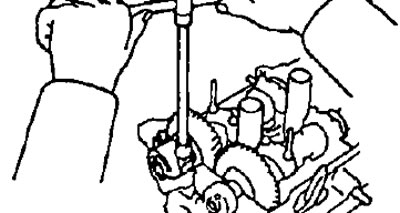

- b) Holding the camshaft with a wrench at the hex section. tighten the toothed pulley bolt.

- Tightening torque - 50 Nm

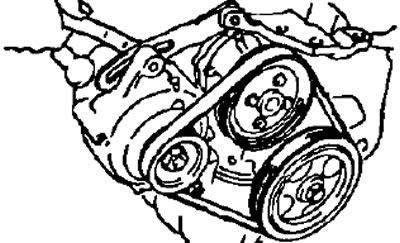

6. Install the intermediate pulley and tighten the bolt.

- Tightening torque - 27 Nm

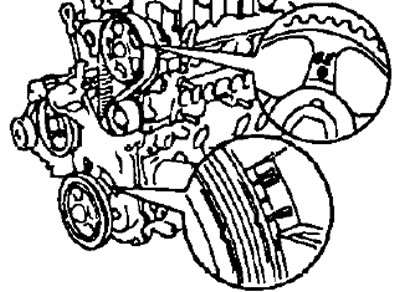

7. Install the timing belt.

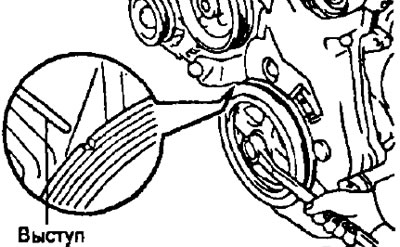

- A) Rotate the crankshaft pulley and align the notch on the pulley with the alignment mark (ledge) on cover #1 of the timing belt.

Note: Check that the timing belt is correctly installed on the crankshaft sprocket and on the oil pump pulley.

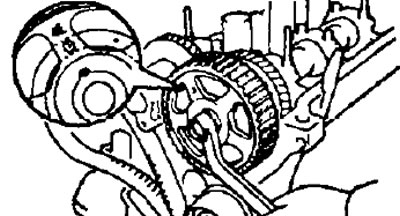

- b) Rotate the camshaft and align the alignment hole on the camshaft sprocket with the alignment mark on the Nel bearing cap.

- V) Place the timing belt on the camshaft sprocket as shown in the illustration and turn the camshaft to install the belt.

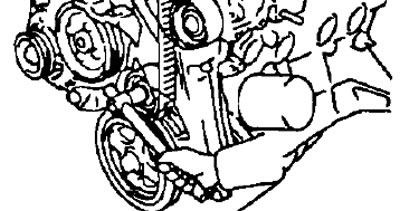

- G) Loosen the idler pulley mounting bolt until it moves slightly under the action of the spring.

- d) Rotate the crankshaft pulley two turns (from TDC to TDC).

Note: Turn the crankshaft only clockwise.

- e) Check that all alignment marks on all pulleys are aligned.

If the alignment marks are not aligned, then remove the timing belt and reinstall it.

8. Install timing belt cover #3.

9. Install the alternator drive belt. Temporarily tighten the axle bolt nut and adjust the belt tension.

10. Install timing belt cover #2 by installing gasket and tighten with four bolts.

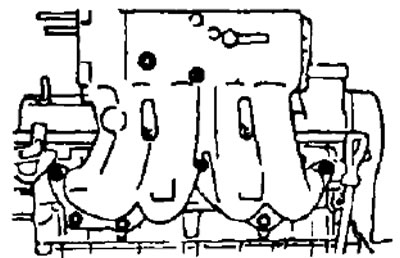

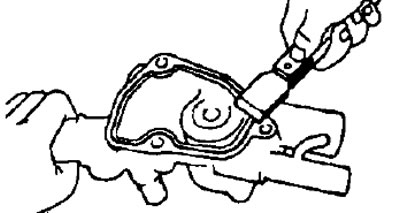

11. Install the cylinder head cover

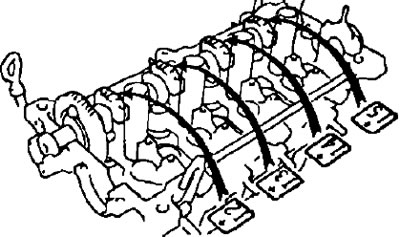

- A) Apply sealant to the cylinder head as shown.

- b) Install the gasket on the cylinder head cover.

- V) Install the cylinder head cover and tighten the five sealing washers.

- Tightening torque - 7 Nm

12. Install the intake manifold.

- A) Install new gasket and intake manifold, tighten three nuts and three bolts

- Tightening torque - 19 Nm

- 6) Install the manifold bracket by tightening the two bolts and nuts.

- Tightening torque - 19 Nm

13. Install the air tube by tightening the two bolts.

14. Install the injectors and fuel manifold.

15. Install the throttle body.

16. Install the air bypass valve to the outlet.

- A) Install the O-ring from the air bypass valve.

- b) Apply soapy water to the O-ring.

- V) Connect two bolts, wire "grounding" and an air bypass valve to the outlet.

- G) Connect the valve connector.

17. Install the exhaust manifold.

- A) Install a new gasket and tighten the six nuts.

- Tightening torque - 47 Nm

- b) Install the heat shield and tighten the three bolts.

- Tightening torque - 8 Nm

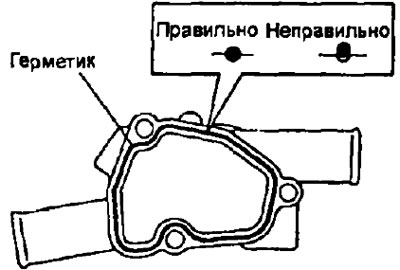

18. Install thermostat and outlet tubes

- A) Remove the old sealing material and clean the surface as shown in the figure.

Note: Use a scraper or scraper to remove and clean surfaces with a non-residue solvent.

- b) Apply sealant as shown.

- e) Install the thermostat and tighten the two bolts.

- Tightening torque - 19 Nm

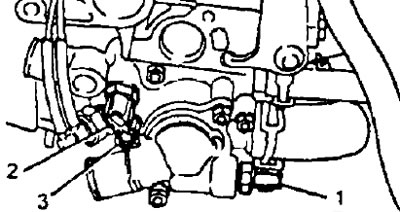

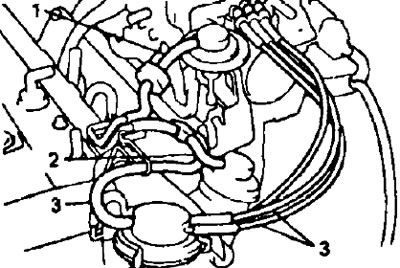

- G) Connect the following hoses:

- Coolant Inlet Hose (1).

- Heater outlet hose (2).

- coolant bypass hose (3)

- Two vacuum hoses of a thermally controlled pneumatic valve (4).

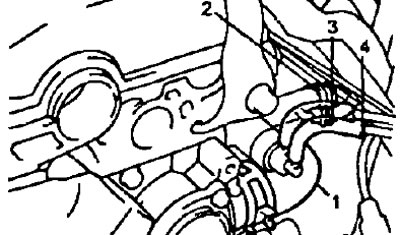

- d) Connect the following connectors:

- Sensor connector - switch for coolant temperature (to the electric fan drive of the cooling system) (1).

- Connector coolant temperature sensor (2).

- Coolant temperature gauge sensor connector (3).

- (Models with automatic transmission) Coolant Temperature Switch Sensor Connector (4).

18. Install the EGR pipe, vacuum modulator and EGR valve.

- A) Install the gasket and EGR valve, tighten the two nuts.

- Tightening torque - 17 Nm

- b) Install the vacuum modulator.

- V) Install a new gasket and EGR pipe by tightening the two fastening nuts. Tighten the union nut of the tube.

- Torque:

- union nut - 39 Nm

- fastening nuts - 29 Nm

19. Connect the vacuum hoses, power steering pump.

- A) (Models with automatic transmission) Connect the following hoses:

- Vacuum hose from throttle actuator (1).

- Vacuum hose from EGR valve (2).

- Three vacuum hoses from the EGR vacuum modulator (3).

- b) Connect the vacuum hose from the fuel vapor accumulator.

20. Install spark plugs.

- Tightening torque - 19 Nm

21. Connect the high voltage wires by tightening the bolt securing the high voltage wire holders to the cylinder head cover.