Removing the timing belt

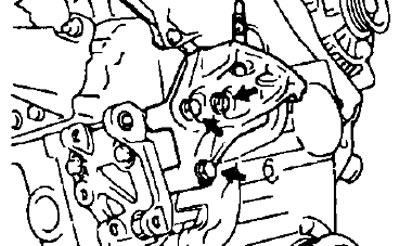

1. Remove the right engine mount by removing the three bolts.

2 Remove the generator.

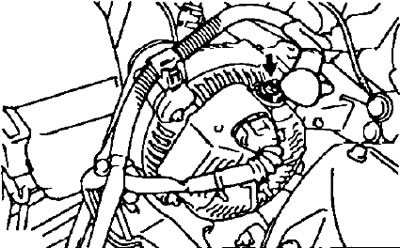

- A) Disconnect the wire harness clamp from the clamp on the alternator

- b) Disconnect the generator connector.

- V) Remove the rubber cap, unscrew the wire fastening nut and disconnect the generator wire.

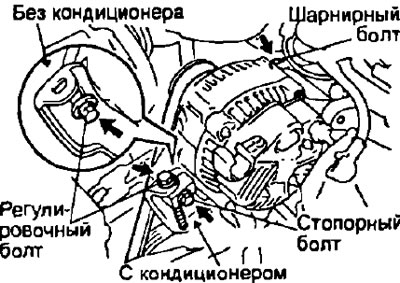

- G) Loosen the lock bolt (models with air conditioning), adjusting bolt and hinge bolt.

- d) Remove the alternator drive belt.

- e) Remove the adjustment stop bolt (models with air conditioning) or adjusting bolt (models without air conditioning) and hinge bolt.

- and) Remove the generator.

3. Turn out spark plugs.

- A) Disconnect the high voltage wires behind the rubber caps. Do not pull high voltage wires.

- b) Remove spark plugs.

4. Remove timing belt cover #2 by unscrewing five bolts and remove two gaskets.

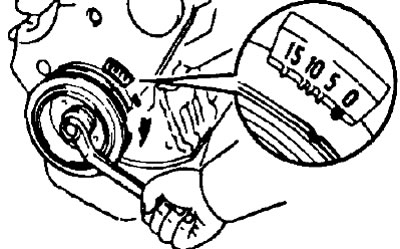

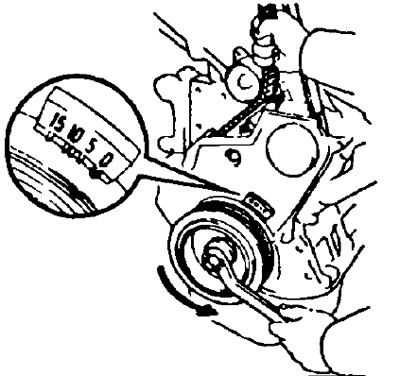

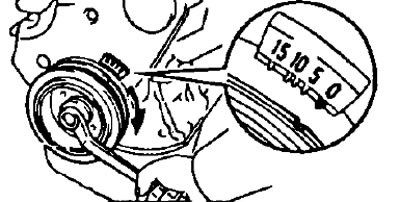

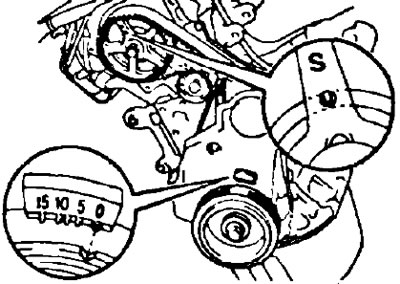

5. Set the piston of cylinder No. 1 to TDC of the compression stroke

- A) Rotate the crankshaft pulley and align its mark with the alignment mark "0" on cover #1 of the timing belt.

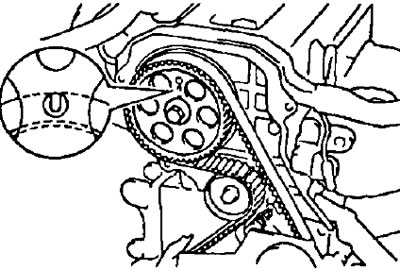

- b) Check that the alignment notch on the camshaft sprocket is aligned with the alignment mark of the bearing cover. If not, turn the crankshaft one turn (360°).

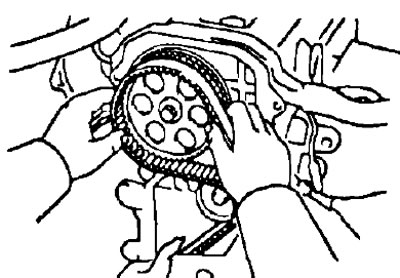

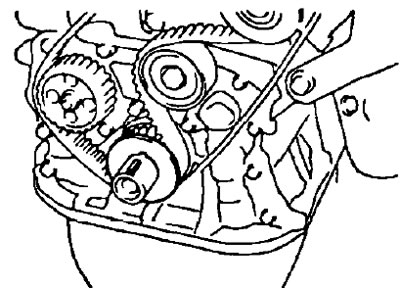

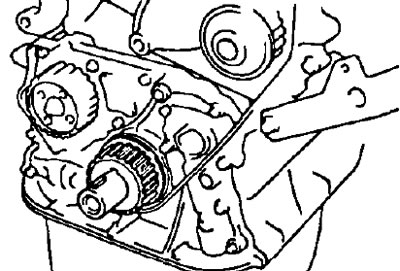

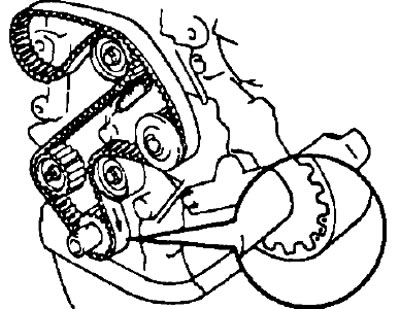

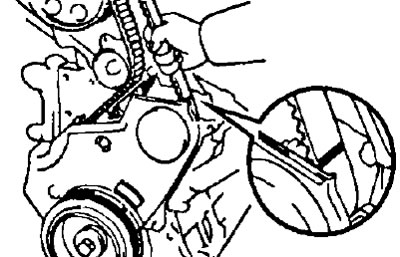

6. Remove the timing belt from the camshaft sprocket.

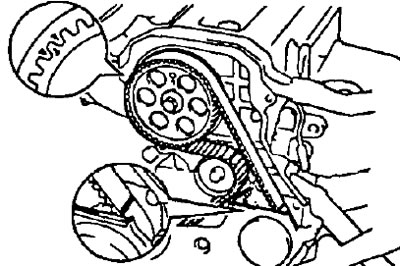

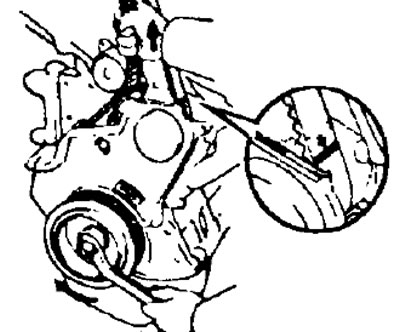

Note, when reusing the timing belt, put an arrow in the direction of rotation, marks on the timing belt and camshaft sprocket and align them with the mark on the timing belt cover No. 1 as shown in the figure.

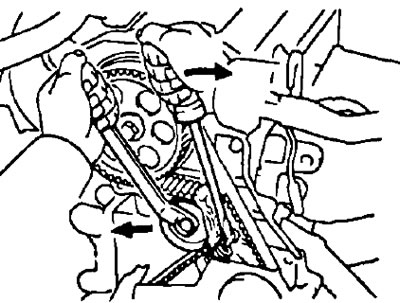

- A) Loosen the idler pulley mounting bolt and, being careful not to damage the belt, push the pulley to the left as far as possible and temporarily tighten the bolt.

- b) Remove the timing belt from the camshaft sprocket.

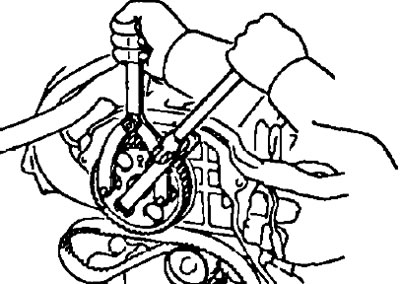

7. If necessary, remove the camshaft pulley by unscrewing the mounting bolt

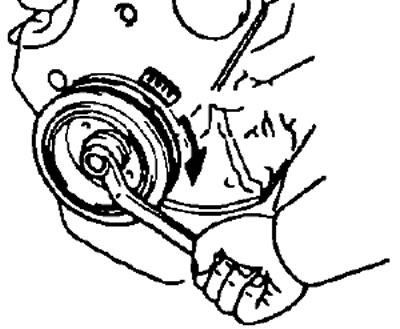

8. Remove the crankshaft pulley.

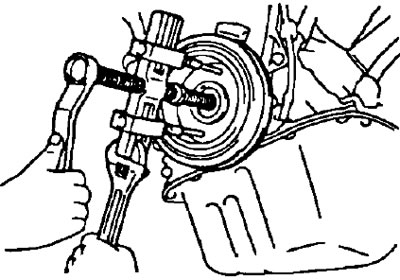

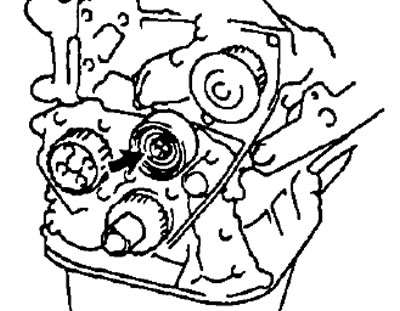

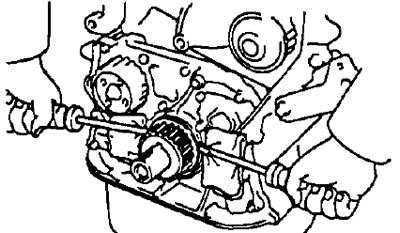

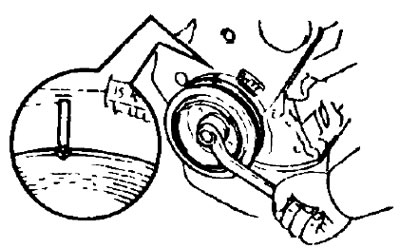

- A) Using the special tool, loosen the pulley bolt.

Note:

- When reusing the timing belt, after loosening the crankshaft pulley bolt, check that the timing belt marks and timing belt cover No. 1 are aligned when the alignment marks are aligned (crankshaft pulley recess and "0" on the cover No. 1 of the timing belt).

- When the bolt is loosened, the crankshaft can turn, and since it is not synchronized with the camshaft, it can bend the valves under certain circumstances.

If the marks are not aligned, then do the following:

Note:

- The crankshaft can only be turned clockwise, but at small angles of rotation and counterclockwise.

- Align the alignment marks as shown in the illustration.

- After aligning the marks, hold the timing belt and turn the crankshaft pulley, aligning its alignment mark with the alignment mark "0" on cover #1 of the timing belt.

- V) Remove the pulley by unscrewing the bolt.

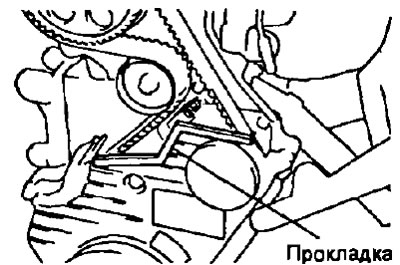

9. Remove the #1 timing belt cover by unscrewing the four bolts and remove the gasket.

10. Remove the timing belt guide.

11. Remove the timing belt.

Note: When reusing the timing belt, draw an arrow on it in the direction of rotation and mark the timing belt and crankshaft sprocket.

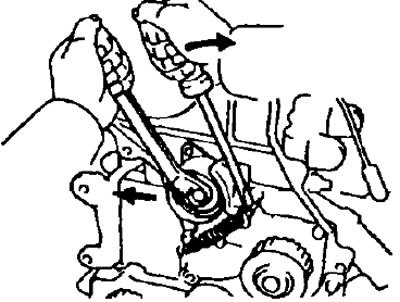

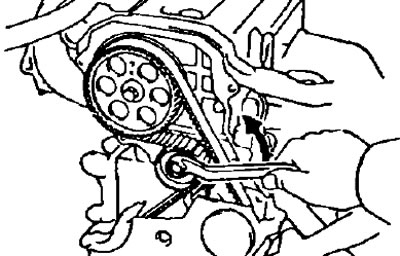

12. Remove the tension roller and tension roller spring by unscrewing the bolt.

13. If necessary, remove the intermediate pulley by unscrewing the bolt.

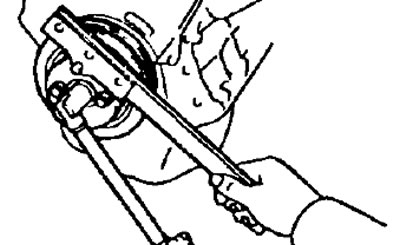

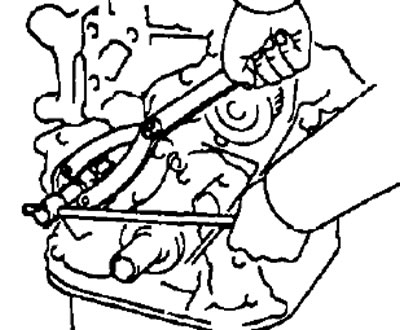

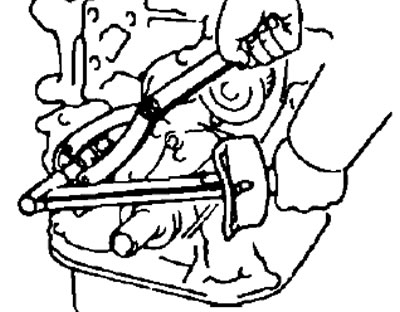

14. If necessary remove a gear pulley of a cranked shaft. If the pulley is difficult to remove by hand, use two screwdrivers.

Note: Lay the rags as shown in the illustration to prevent damage.

15. If necessary, remove the oil pump pulley by unscrewing the nut.

Timing belt installation

1. Install the oil pump pulley if removed

- A) Align the pulley and shaft profiles and install the pulley.

- b) Tighten the oil pump pulley nut.

- Tightening torque - 28 Nm

2. Install the crankshaft sprocket (if it was taken).

- A) Align the dowel key on the crankshaft with the keyway in the pulley.

- b) Install the crankshaft sprocket of the belt guide inward

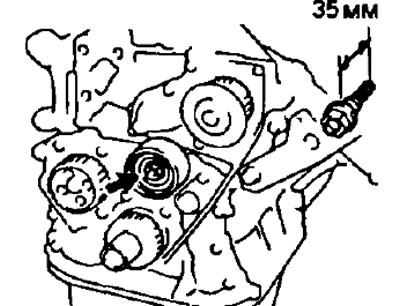

3. Install the intermediate pulley. (If it was taken).

- A) Install the pulley and tighten the bolt.

- Tightening torque - 42 Nm

Note: Use a 35mm long bolt.

- b) Check that the pulley rotates freely.

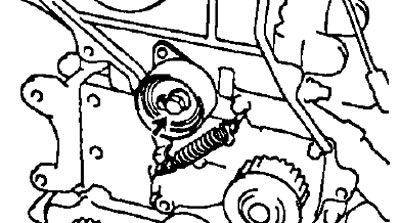

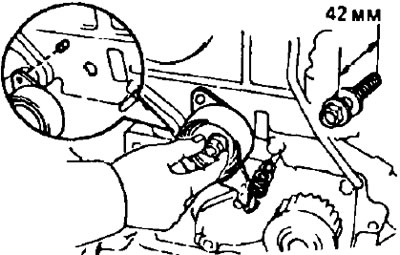

4. Temporarily install the tension roller and its spring.

- A) Align the hole with the guide pin.

- b) Install the tension roller and bolt. Do not tighten the bolt.

Note: Use a 42mm long bolt.

- V) Install the tension roller spring.

- G) Press the roller to the left as far as possible and tighten the bolt.

- d) Check that the tension roller rotates freely.

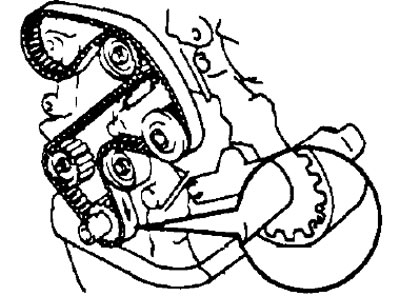

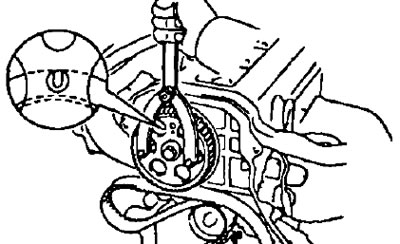

5. Temporarily install the timing belt.

- A) Turn the crankshaft at the pulley bolt and align the timing marks on the crankshaft toothed pulley with the marks on the oil pump housing.

- b) Remove any oil or water from the crankshaft pulley, oil pump pulley, coolant pump pulley, #1 and #2 tensioner pulley.

- V) Install the timing belt to the crankshaft sprocket, oil pump pulley, tensioner pulley #1, coolant pump pulley and tensioner pulley #2.

Note: When reusing the timing belt, align the marks made during removal and install the belt with the arrow pointing in the direction of rotation of the engine crankshaft.

6. Install the timing belt guide facing out.

7. Install timing belt cover #1.

- A) Install or glue the gasket to the timing belt cover.

Note: If the gasket is swollen or resized due to an oil leak, cut off the excess.

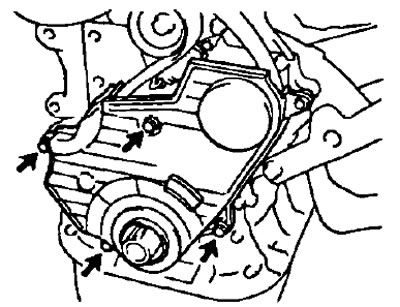

- b) Install the timing belt cover and tighten the four bolts.

8. Install the crankshaft pulley.

- A) Align the pulley key with the groove on the pulley and install the pulley.

- b) Tighten the pulley bolt.

- Tightening torque - 108 Nm

9. Establish a gear pulley of a camshaft.

- A) Align the camshaft locating pin with the pin hole and install the camshaft sprocket.

- b) Tighten the pulley bolt.

- Tightening torque - 54 Nm

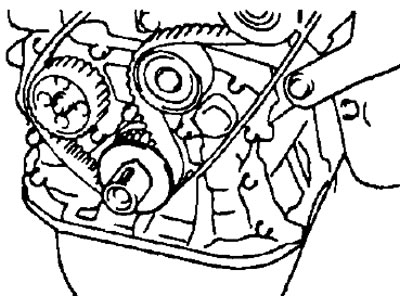

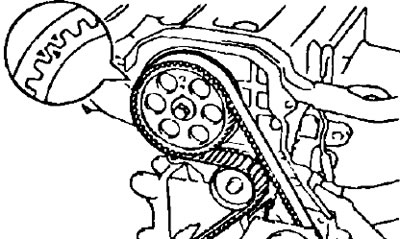

10. Set the piston of cylinder No. 1 to TDC of the compression stroke.

- A) Rotate the crankshaft pulley and align it with the alignment mark "0" on cover #1 of the timing belt.

- b) Using the special tool, rotate the camshaft and align the camshaft sprocket bore with the bearing cap alignment mark.

11. Install the timing belt on the camshaft sprocket

Note: When reusing the timing belt

- Check that the marks on the timing belt and the cover are aligned. If necessary, reinstall the timing belt until they are aligned

- Align the marks on the timing belt and camshaft sprocket.

|  |

- A) Remove, if any, oil or water from the camshaft sprocket

- b) Install the timing belt on the camshaft sprocket, controlling the tension of the working branch between the crankshaft sprocket and the camshaft sprocket.

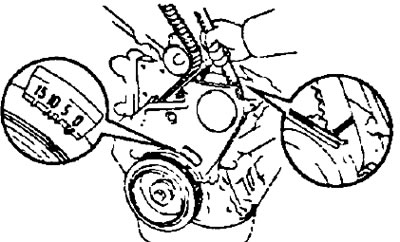

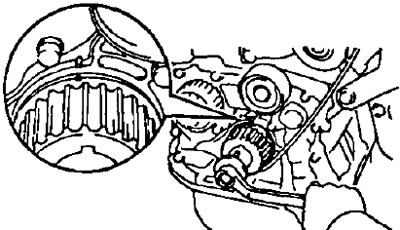

12. Check the valve timing.

- A) Loosen the tension roller by turning the bolt 1/2 turn.

- b) Slowly turn the crankshaft pulley two turns from TDC to TDC.

Note: always turn the crankshaft pulley clockwise, otherwise the roller will 'play', the belt will get slack and slip a tooth.

- V) Check that each pulley is aligned with the timing marks as shown in the illustration. If the alignment marks are not aligned, remove the timing belt and reinstall it.

- G) Slowly turning the crankshaft pulley 1 and 7/8 turns, align it with the mark 45°to TDC (for cylinder #1) on cover No. 1 of the timing belt.

Note: Always turn the crankshaft pulley clockwise.

- d) Tighten the idler pulley bolt.

- Tightening torque - 42 Nm

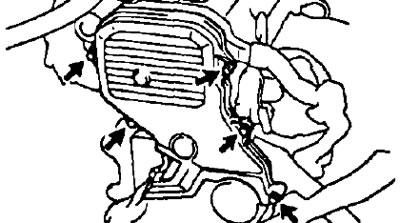

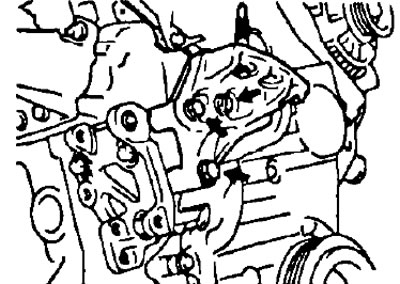

13. Install timing belt cover #2

- A) Install the gasket on the timing belt cover N81.

Note: it is better to glue the gasket so that it does not come off inward.

- b) Disconnect the wire harness guard from the cylinder head and timing belt cover #3.

- V) Install the timing belt cover by tightening the four bolts.

- G) Install the two wire harness clamps.

- d) Install the engine wiring harness protection clamps to the two bolts securing the #2 timing belt cover in the sequence shown in the figure.

14. Install the spark plugs and connect the high voltage wires to the spark plugs.

- Tightening torque - 18 Nm

15. Install the right engine mount by tightening the three bolts.

- Tightening torque - 52 Nm

16. Install the generator.

- A) Install the generator on the hinge, locking bolts (models with air conditioning) or adjusting screw (models without air conditioning). Do not overtighten the bolts.

- b) Install the alternator drive belt and adjust its tension.

- V) Tighten all bolts.

- Torque:

- hinge bolt - 54 Nm

- locking and adjusting bolt - 19 Nm

- G) Connect the generator connector.

- d) Connect the alternator wire by tightening the wire fastening nut and install the rubber cap.

- e) Connect the wire harness clamp to the clamp on the alternator.