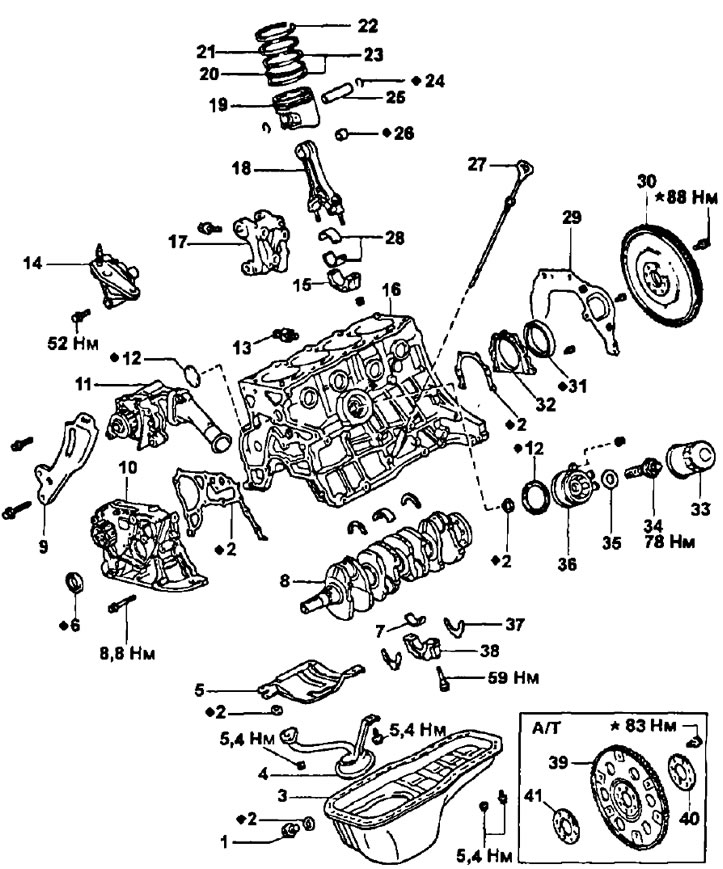

Cylinder block; parts for disassembly and assembly. 1 - drain plug; 2 - gasket; 3 - oil pan; 4 - oil receiver 5 - oil damper; 6 - front crankshaft oil seal; 7 - main bearing; 8 - crankshaft; 9 - adjusting bracket for the generator drive belt; 10 - oil pump; 11 - coolant pump and coolant pump cover assembly; 12 - ring seal; 13 - knock sensor; 14 - right engine mount; 15 - bottom cover of the connecting rod; 16 - cylinder block; 17 - hydraulic booster pump bracket; 18 - connecting rod; 19 - piston; 20 - oil scraper ring expander; 21 - compression ring No. 2; 22 - compression ring No. 1; 23 - scrapers of the oil scraper ring; 24 - retaining ring; 25 - piston pin; 26 - bushing of the upper head of the connecting rod; 27 - oil dipstick; 28 - connecting rod bearing; 29 - back plate; 30 - flywheel (models with manual transmission); 31 - rear crankshaft oil seal; 32 - holder of the rear oil seal; 33 - oil filter; 34 - safety valve; 35 - lamellar washer; 36 - oil cooler; 37 - persistent half ring; 38 - main bearing cap; 39 - torque converter drive plate; 40 - back plate; 41 - spacer sleeve.

Operations before disassembly

1 Remove the flywheel (models with manual transmission) or torque converter drive plate (models with automatic transmission).

Note: before removing the flywheel or torque converter drive plate, set marks so as not to disturb the balance when installing them.

2. Remove the back plate by unscrewing the bolt.

3. Install the engine on a stand for disassembly.

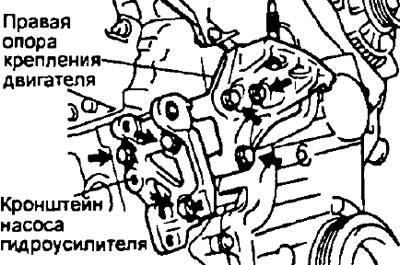

4. Turn away three bolts and remove the right support of fastening of the engine.

5. Turn away three bolts and remove, an arm of the pump of the hydraulic booster.

6. Remove the timing belt and pulleys.

7. Remove the cylinder head.

8. Remove the oil pan and oil pump.

- A) Remove the dipstick and remove the bolts and nuts.

- b) Remove the oil pan by inserting a blade between the cylinder block and the oil pan, being careful not to damage the contact surfaces.

- V) Remove two bolts and two nuts and remove the oil receiver, oil damper and gasket.

- G) Turn away bolts.

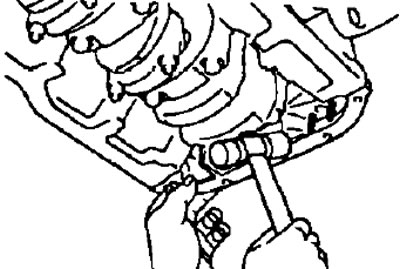

- d) Tap the oil pump housing with a plastic-headed hammer to remove the oil pump.

- e) Remove the gasket.

9. Remove the alternator drive belt adjuster bracket, water pump, and water pump cover assembly.

- A) Turn away a bolt and remove an adjusting arm.

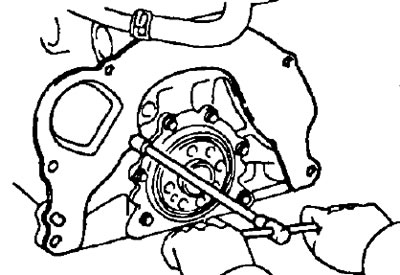

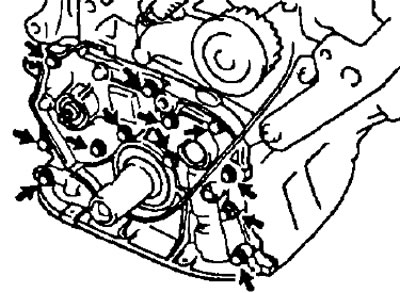

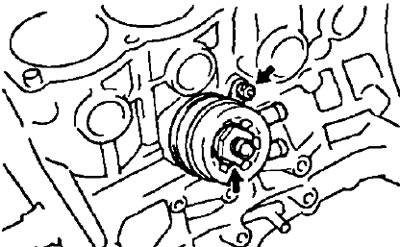

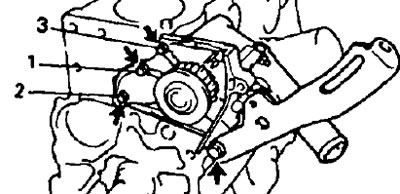

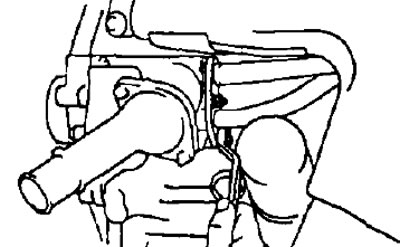

- b) Remove the three bolts in the sequence shown in the figure, remove the water pump assembly, water pump cover and O-ring.

10. Remove the oil filter.

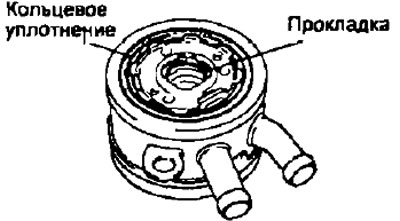

11. (Models with oil cooler) Remove the oil cooler.

- A) Remove relief valve and plate washer.

- b) Loosen the nut and remove the oil cooler.

- V) Remove the O-ring and gasket from the oil cooler.

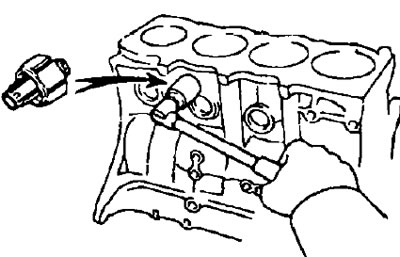

12. Remove the knock sensor.

Final assembly

1. Install the knock sensor.

- Torque:

- 3S-FE, 4S-FE - 37 Nm

- 3S-GE - 44 Nm

2. (Models with oil cooler) Install the oil cooler.

- A) Clean the contact surface of the skimmer and cylinder block.

- b) Install a new O-ring and gasket to the oil cooler.

- V) Apply a thin film of engine oil to the threads and under the relief valve head.

- G) Temporarily install the oil cooler by lightly tightening the nut.

- d) Install the plate washer and relief valve.

- Tightening torque - 78 Nm

- e) tighten the nut (M3=8 Nm).

3. Install the oil filter.

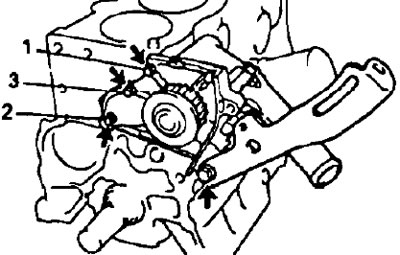

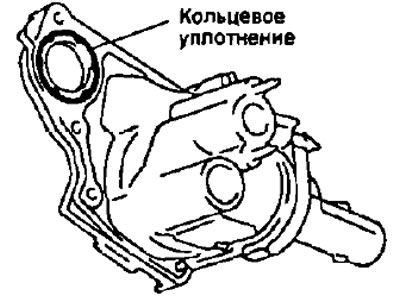

4. Install the water pump, water pump cover assembly.

(3S-FE, 4S-FE)

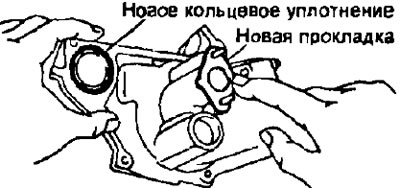

- A) Install a new O-ring on the water pump cover.

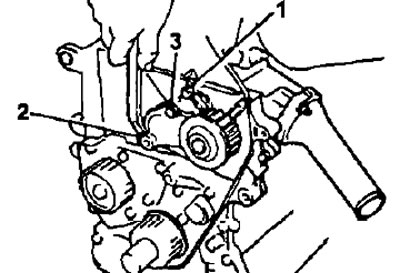

- b) Install the water pump by tightening the three bolts. Tighten the bolts in the sequence shown in the figure (M3=8 Nm).

- V) Install the adjustment bracket by tightening the bolt (М3=27 Nm).

(3S-GE)

- A) Install a new O-ring and gasket to the water pump cover.

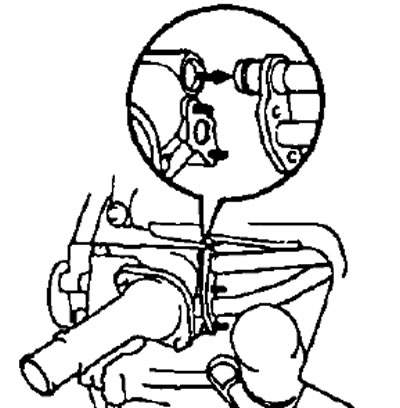

- b) Install a new O-ring on the coolant bypass pipe and apply soapy water to the seal.

- V) Connect the bypass tube to the coolant pump cover.

- G) Install the water pump by tightening the three bolts in the sequence shown in the figure (М3=9 Nm).

- d) Tighten the two bypass tube mounting bolts (М3=9 Nm).

5. Install the oil pump and oil pan

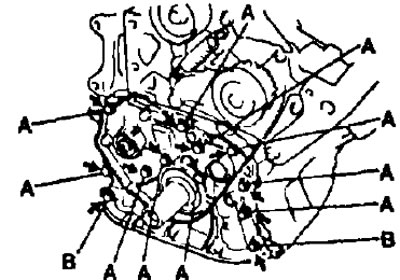

- A) Install new gasket and oil pump Tighten bolts in several passes (М3=9 Nm).

Note: bolt lengths are different:

- bolt "A" - 25 mm

- bolt "B" - 35 mm

- b) Install a new gasket, oil receiver and oil separator by tightening the two nuts and two bolts.

- Tightening torque - 6 Nm

- V) Remove the remaining sealing material and do not allow oil to get on the contact surfaces of the oil pan and cylinder block.

- Use solvent to clean the contact surfaces.

Note: Do not use solvent. which can damage painted surfaces.

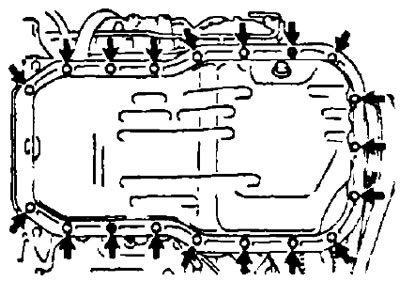

- G) Apply sealant to the contact surface of the oil pan as shown in the illustration.

Note: The mating parts must be assembled within 5 minutes after applying the sealant. Otherwise the material must be removed and reapplied.

- e) Install the oil pan and tighten the two nuts and eight bolts.

- Tightening torque - 5.5 Nm

- and) Install the oil dipstick.

6. Install the cylinder head.

7. Install the timing belt and pulleys.

8. Install the right engine mount by tightening the three bolts (М3=52 Nm).

9. Install the power steering pump bracket by tightening the three bolts.

- Tightening torque - 43 Nm

10. Remove the engine from the stand.

11. Install the back plate by tightening the bolt (М3=9 Nm).

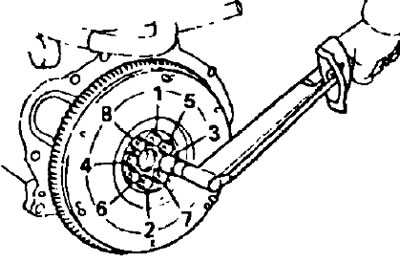

12. (Models with manual transmission) Install the flywheel.

- A) Apply special fixing adhesive to 2 or 3 bolt threads.

- b) Install the flywheel on the crankshaft

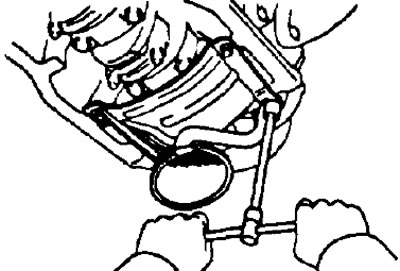

- V) Install and evenly tighten the 8 bolts in several passes in the sequence shown in the figure (М3=88 Nm).

13. (Models with automatic transmission) Install the torque converter drive plate (М3=83 Nm)