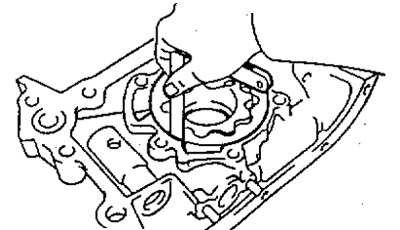

After lubricating the surface of the valve with fresh engine oil, install it in the mounting hole and make sure that the valve drops under its own weight.

If it doesn't, replace the valve or the entire oil pump.

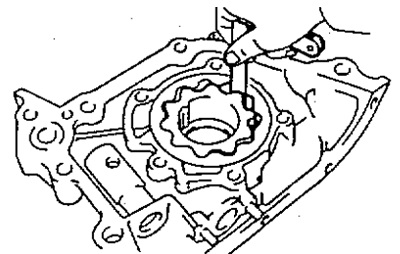

2. Check the male and female rotors.

Check the following clearances:

Radial clearance between driven rotor and housing:

nominal:

- 3S-FE, 4S-FE - 0.100 0.160 mm

- series A - 0.080-0.180 mm

- 2C - 0.100-0.170 mm

maximum allowable:

- 3S-FE, 4S-FE - 0.200 mm

- series A - 0.200 mm

- 2C - 0.200 mm

* Radial clearance between the protrusions of the leading and driven rotors:

nominal:

- 3S-FE, 4S-FE — 0,040 - 0,160

- series A - 0.025 - 0.085 mm

- 2C - 0.050 - 0.150 mm

maximum allowable:

- 3S-FE, 4S-FE - 0.200 mm

- series A - 0.0350 mm

- 2C - 0.200 mm

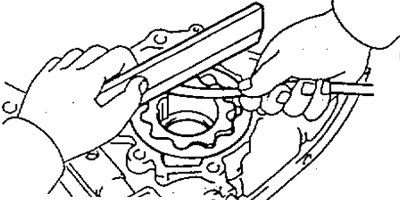

End gap between rotors and housing wall:

nominal:

- 3S-FE, 4S-FE - 0.025 - 0.075 mm

- series A - 0.025 - 0.085 mm

- 2C - 0.030 - 0.090 mm

maximum allowable:

- 3S-FE, 4S-FE - 0.100mm

- series A - 0.100 mm

- 2C - 0.150 mm

If any gap is greater than maximum, replace both gears. Replace the entire pump if necessary.