2. Check the quality of the injection nozzles.

Note: Avoid sparks during testing. Keep a fire extinguisher ready.

A) Prepare the necessary service tools.

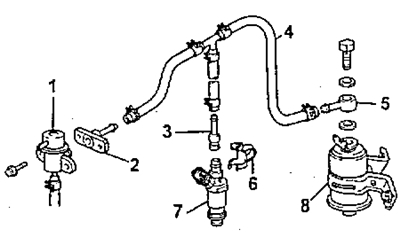

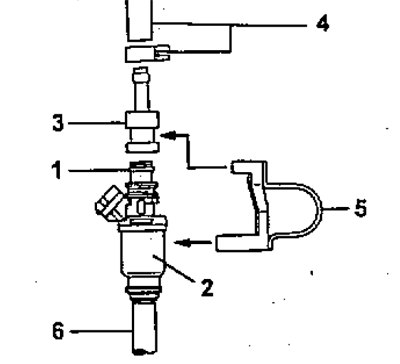

Injector test scheme (4A-FE, 5A-FE, 7A-FE)

1 - fuel pressure regulator (remove from car),

2 - fitting-adapter to the regulator,

3 - fitting-adapter to the nozzle,

4 - Service hose,

5 - fitting-adapter to the fuel filter,

6 - clamp for fixing the nozzle,

7 - nozzle,

8 - fuel filter.

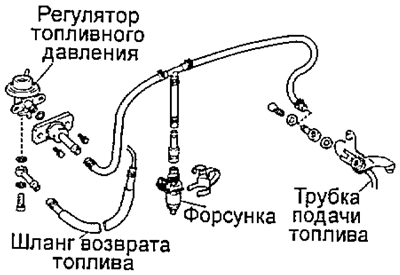

Injector test scheme (3S-FE, 4S-FE)

(4A-FE, 5A-FE and 7A-FE)

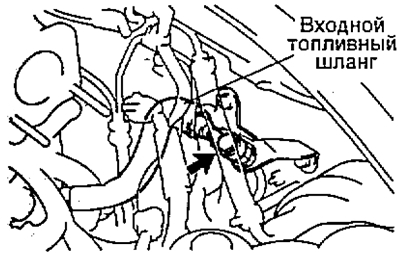

b) Disconnect the fuel inlet hose from the fuel filter.

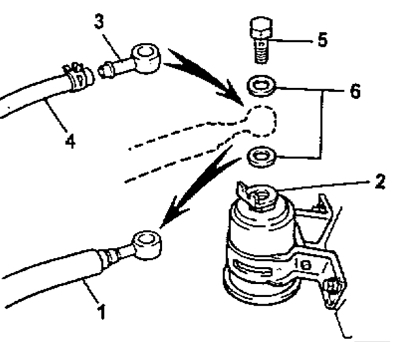

V) Connect the adapter (3) and service hose (4) to the fuel filter outlet (2) with a bolt (5), installed with new gaskets (6).

- Tightening torque - 29 Nm

Note: Use the vehicle's fuel filter.

(3S-FE, 4S-FE)

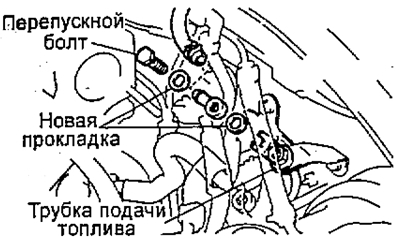

b) Remove the bypass bolt, remove the 2 gaskets, and disconnect the fuel inlet hose from the fuel feed pipe.

Note: When removing the bypass bolt, hold the fuel filter in place with a wrench.

V) Connect the adapter fitting and service hose to the fuel supply pipe using two new gaskets and bypass bolts.

- Tightening torque - 29 Nm

(All engines)

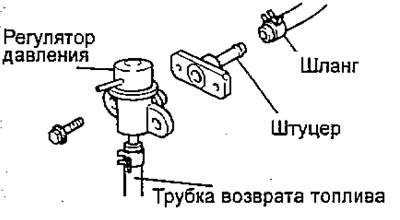

Disconnect the fuel pressure regulator from the fuel manifold and connect a service hose to it using an adapter fitting, attaching it to the regulator with 2 bolts.

- Tightening torque - 9 Nm

Connect fuel return hose (4) to the regulator.

Note: Install new gaskets on the fuel pressure regulator.

d) Install a new safety sleeve and a new O-ring (1) on the nozzle (2).

e) Connect the adapter fitting; (3) and service hose (4) to nozzle; (2), secure the nozzle with the clamp (5).

and) Install the nozzle in a measuring container. Put on a suitable vinyl hose (6) on the injector to prevent fuel splashing.

h) Connect (-) wire to negative (-) terminal to the battery, battery and turn on the ignition.

Note: do not start the engine.

And) Jumper short the terminals "FP" And "+V" diagnostic socket.

To) Connect the service wire to the injector and battery for 15 seconds, measure the volume of fuel injected into the measuring vessel. Repeat the test 2-3 times for each injector.

Volume of injected fuel:

- 3S-FE, 4S-FE - 49-52 cm3 for 15 s

- 4A-FE, 5A-FE - 54-64 cm3 for 15 s

- 7A-FE - 54-64 cm3 for 15 s

The difference in flow between nozzles is up to 5 cm3

If the fuel supply is out of range, replace the injector.

3. Check for leaks.

A) At the end of the previous check, disconnect the wires from the battery and check for fuel leakage through the injector.

Leak no more than 1 drop in 1 minute

b) Switch off the ignition, remove the jumper from the diagnostic connector and disconnect (-) wire from the negative battery terminal.

V) Remove adapter fittings and service hoses.

G) (4A-FE, 5A-FE and 7A-FE) Connect the fuel hose to the fuel filter outlet by tightening the bypass bolt.

- Tightening torque - 29 Nm

d) (3S-FEt 4S-FE) Connect the fuel inlet hose to the fuel feed pipe using 2 new gaskets and a bypass bolt.

- Tightening torque - 29 Nm

Note: When removing or installing the bypass bolt, hold the fuel filter in place with a wrench.

4. Check the operation of the injectors.

A) Apply 12 V to the injector from the battery and "dry" a clear click, conclude that the injector is working. If there is a dull or indistinct click, the nozzle must be washed.

Attention:

- - A large current passes through the nozzle winding, so it is impossible to (more than 0.5 sec) supply power to it, otherwise it will overheat and burn out.

- - Apply voltage for a short time (poke the wire into the leads and immediately remove).