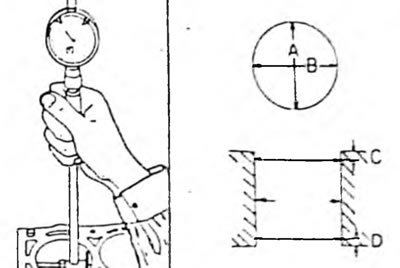

Pic. 89. Measuring cylinders. Pay attention to the depth measurements on the right side

Measure the cylinders in the longitudinal and transverse directions. In addition, measurements should be taken 10 mm from the top edge, 10 mm from the bottom edge and in the middle. A total of 6 measurements are required. Record all measurement results and compare with the data given in the size and adjustment tables. It should be noted that all cylinders must be bored, even if the dimensions of only one cylinder deviate. If the size deviates by 0.20 mm from the required value, the cylinder must be bored. Pistons have only one repair size.

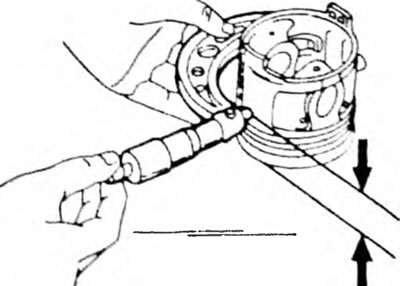

The final cylinder size is determined by measuring the piston according to Figure 90, i.e. 25.4 mm from the piston surface on a 2.0 L engine or 38.5 mm on a 1.4 L engine. Measurements are taken under the lowest groove of the piston. The piston clearance of 0.06 - 0.08 mm for a 1.6 l engine or 0.045 - 0.065 mm for a 2.0 l engine should be added to the measured value. In addition, when boring cylinders, an allowance of 0.02 mm for final honing should be taken into account.

Pic. 90. Measuring the diameter of the piston. The size between the arrows should match the value in the text

To check piston play, measure the cylinder diameter and piston diameters as described above and calculate the difference for each cylinder. If the result exceeds 0.20 mm, the cylinders should be bored to install larger pistons (only one size available), since the backlash has reached the wear limit.