Removing

1. Remove the cylinder head cover, ignition distributor, timing belt, camshaft sprocket and upper section of rear timing belt cover.

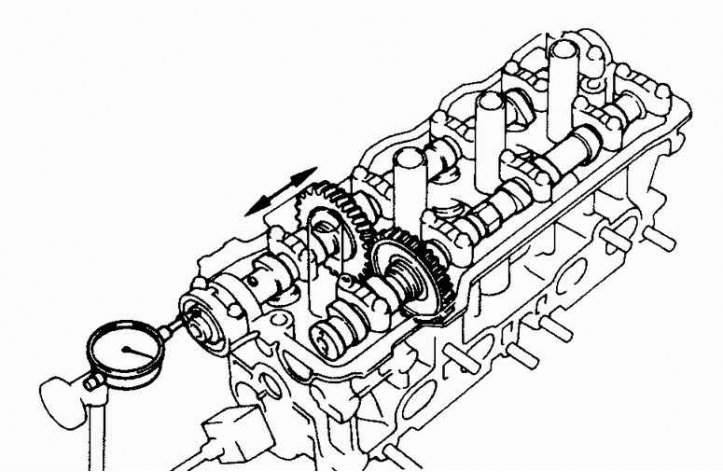

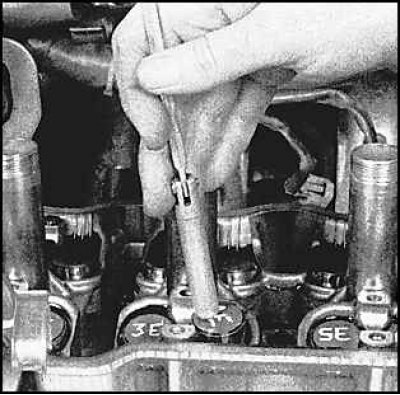

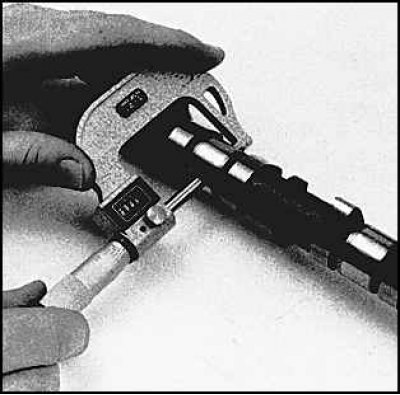

2. Measure the axial clearance of the shaft using a special device. If the clearance is out of specification, replace the shaft and/or cylinder head. Attach the measuring device as shown in the figure.

Exhaust camshaft

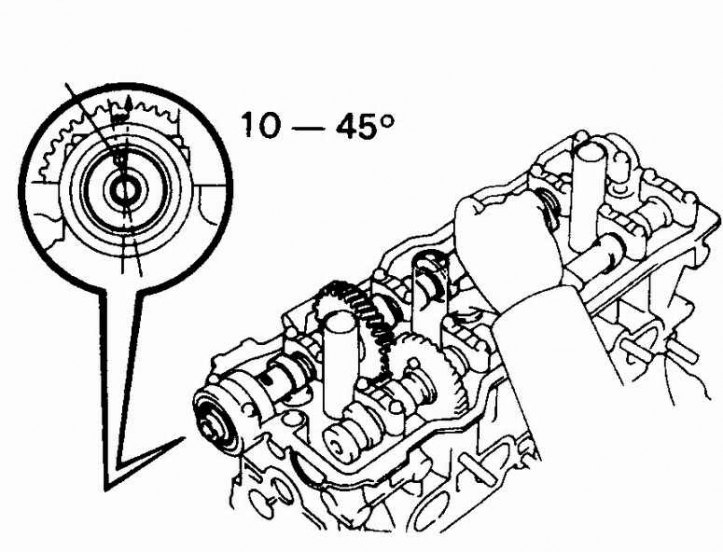

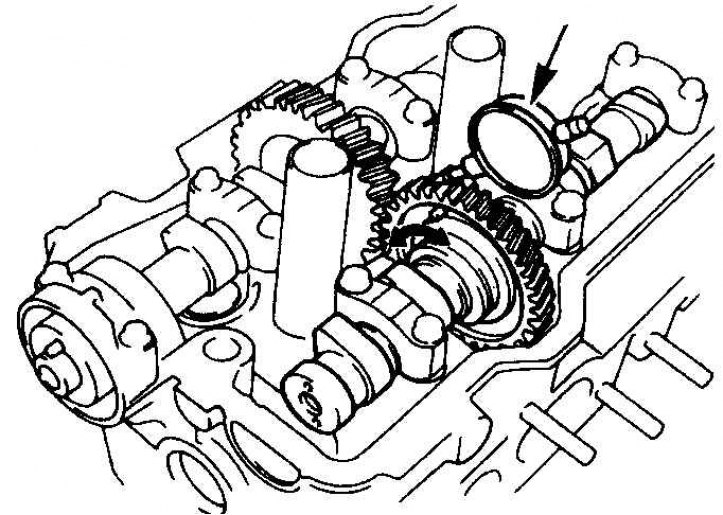

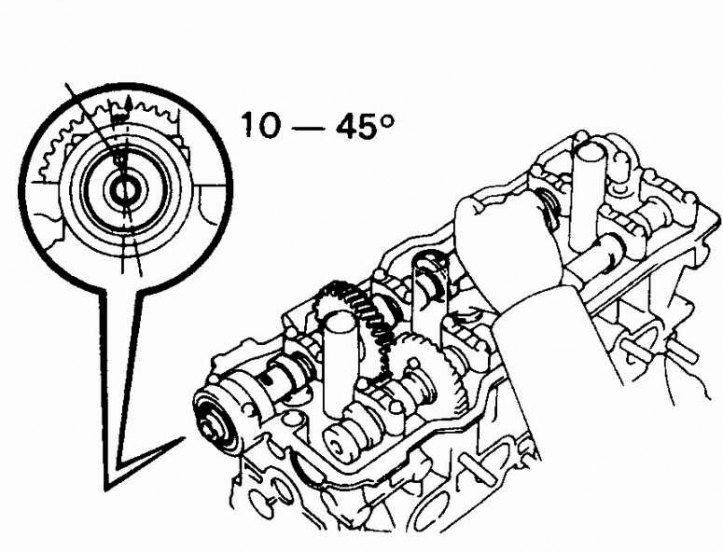

1. Turn the intake valve shaft so that the pin located at the base of the shaft is rotated 10–45°to the left of the vertical position. Now the lobes of the exhaust valve shaft will be positioned so that the pressure of the valve springs will help to remove the shaft with less effort.

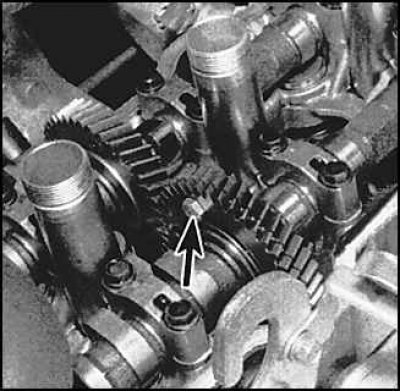

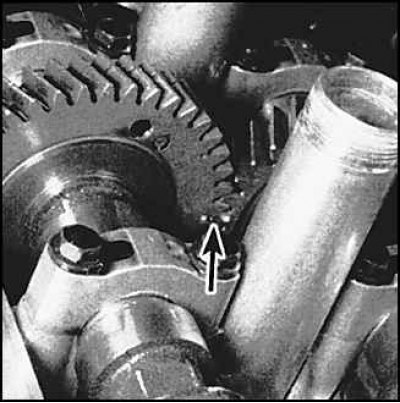

2. Install the exhaust valve shaft auxiliary gear by inserting the bolt (arrow) into its hole and into the hole of the main gear.

3. Unscrew the bolts of the rear bearing cover of the exhaust valve shaft and remove the cover.

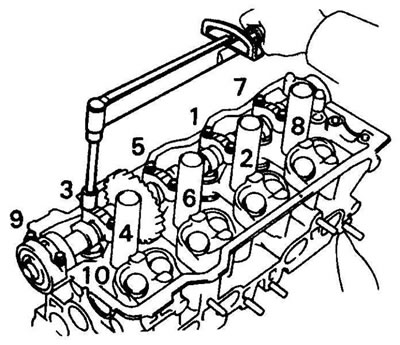

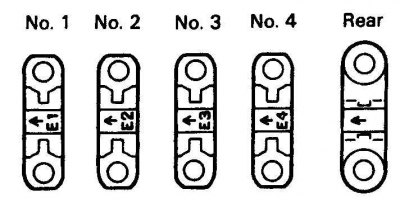

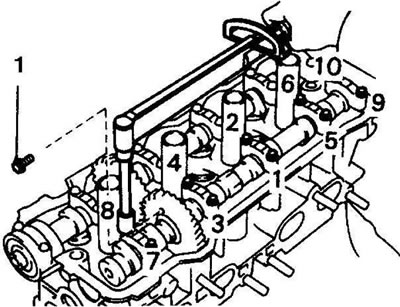

4. Loosen cap screws N1, N2 and N4 one by one. Unscrew the bolts and remove the covers.

5. Loosen the N3 cover bolts, unscrew the bolts and remove the cover.

6. Remove the shaft.

Inlet camshaft

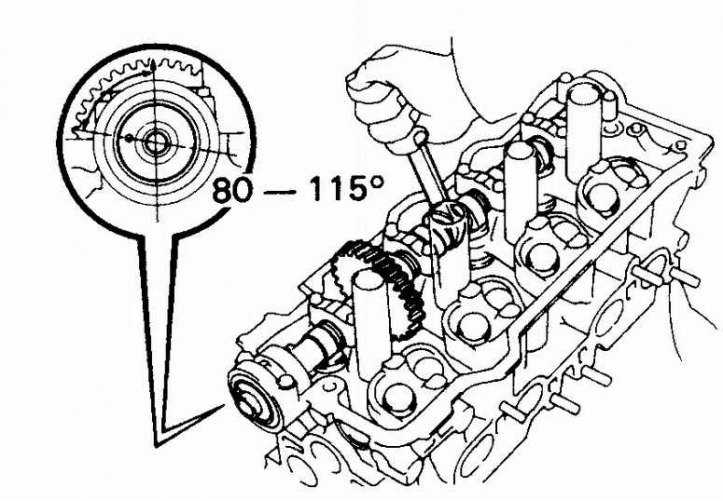

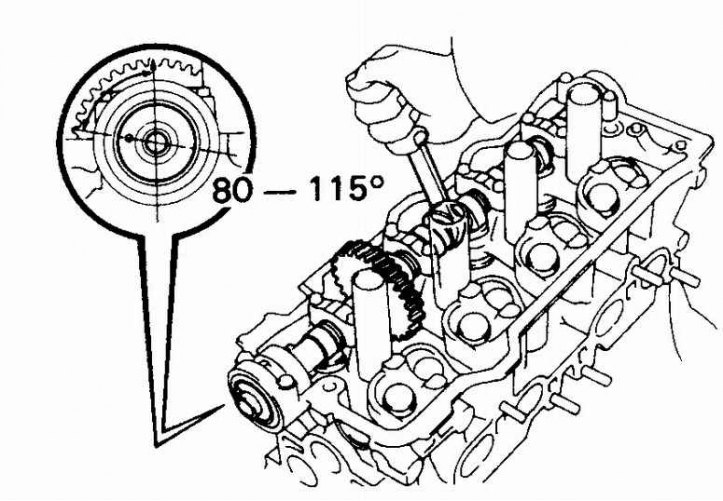

1. Turn the intake valve shaft so that the pin located at the base of the shaft is rotated 80–115°to the left of the vertical position.

2. Unscrew the bolts of the front shaft bearing cover, remove the cover and the oil seal.

3. Loosen cap screws N1, N3 and N4 one by one. Unscrew the bolts and remove the covers.

4. Loosen the cover bolts N2, unscrew the bolts and remove the cover.

Examination

1. Measure the end clearance of the camshaft gear spring. Compare the result with the technical requirements.

2. Wipe the oil off the gaskets, number and remove the valve lifters and gaskets. Use a magnet to remove.

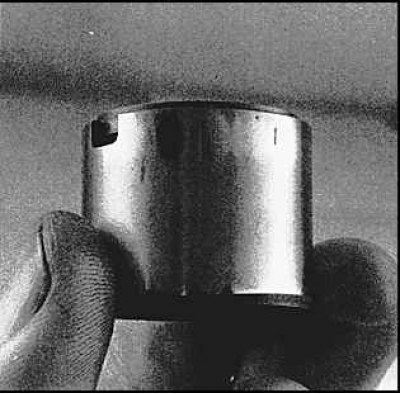

3. Inspect lifters for wear and scratches.

4. Measure the diameters of the lifters and the internal diameters of their respective sockets. By subtracting the diameter of the lifter from the diameter of the seat, you will get the lubrication gap. Compare clearances with specifications. If the gaps are out of specification, the head and/or lifters must be replaced.

5. Put the lifters in a separate box, do not mix up the lifter gaskets.

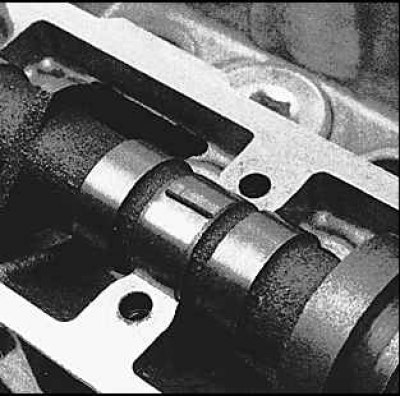

6. Inspect the cams and camshaft bearing journals for wear and damage.

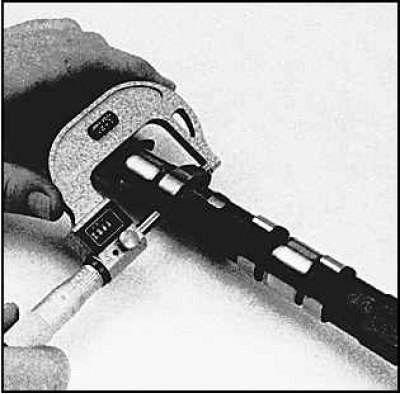

7. Using a micrometer, measure the height of each cam. Compare the obtained values with the technical specifications, if necessary, replace the shaft.

8. Using a micrometer, measure the diameters of the bearing journals. Compare the obtained values with the technical specifications, if necessary, replace the shaft.

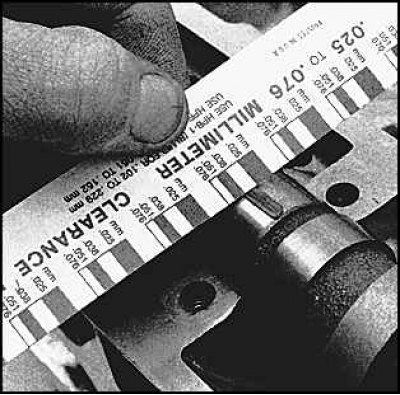

9. Place a plastic measuring tape on the bearing journal.

10. To determine the lubrication gap, measure the width of the crushed strip of plastic using a special scale. If necessary, replace the camshaft and/or cylinder head.

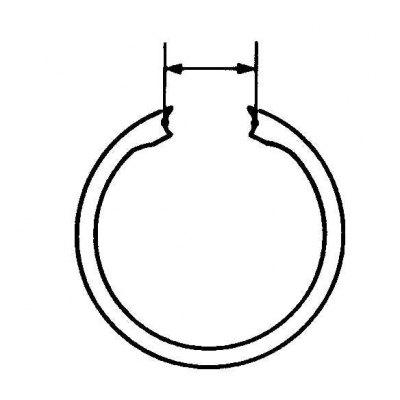

11. Measure the gap between the teeth of the shaft gears using a special tool. Install the measuring device as shown in the figure. Compare the obtained value with the technical specifications.

Installation

Inlet camshaft

1. Lubricate the cams and shaft bearing journals with molybdenum grease, lubricate the lifters and reinstall them.

2. Install the shaft into the cylinder head. The pin at the base of the shaft must be rotated 80°to the left of the vertical position.

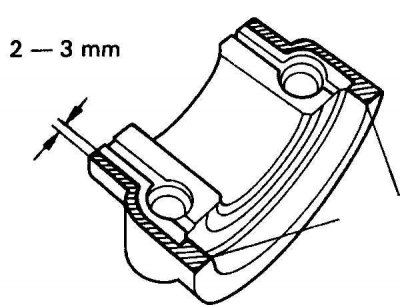

3. Apply sealant to the outer edge of the mating surface of the first bearing cap (marked with hatching).

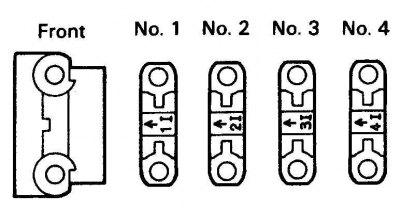

4. Install bearing caps in numerical order. The arrows on the covers must point towards the timing belt.

5. Tighten the cover bolts to the required tightening torque. Tighten the bolts in sequence one fourth of a turn at a time.

6. Install a new oil seal.

Exhaust camshaft

1. Assemble the shaft gear.

2. Lubricate the cams and shaft bearing journals with molybdenum grease, lubricate the lifters and reinstall them.

3. Rotate the intake valve shaft so that the pin at its base of the shaft is rotated 10°to the left of the vertical position.

4. Align the gears of the shafts using the timing marks (arrow). Install the exhaust valve shaft. Rotate the intake valve shaft back and forth to seat the exhaust valve shaft.

5. Install bearing caps in numerical order. The arrows on the covers must point towards the timing belt.

6. Tighten the cover bolts to the required tightening torque. Tighten the bolts in sequence one fourth of a turn at a time.

7. Remove the bolt securing the exhaust valve shaft gears.

8. Install the remaining parts.