2. On 5S-FE engines, remove the balancer assembly.

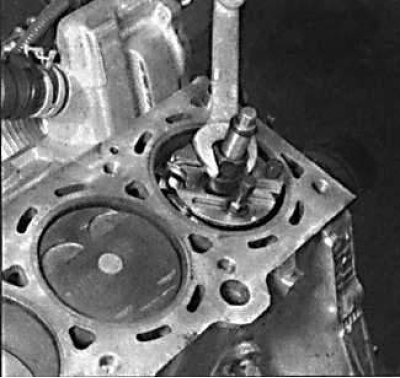

3. If there is carbon on the top of the cylinder, remove it with a soft scraper or special tool. The presence of a step in the upper part of the cylinder indicates excessive wear of the cylinder and the need to bore the engine cylinder.

4. Turn the engine over with the crankshaft up.

|  |

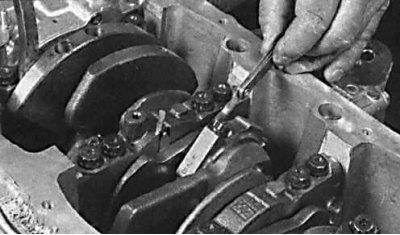

5. Check the side clearance of all connecting rod ends.

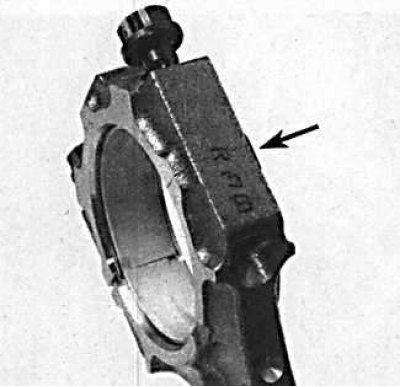

6. Using a hammer and center punch or paint, mark the position of the connecting rod cap and cylinder number.

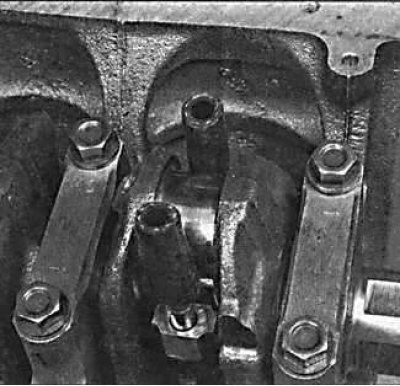

7. Unscrew nuts of fastening of a cover of the bottom head of a rod of the first cylinder. Remove the lower connecting rod cover.

8. To protect the necks of the crankshaft and cylinder liners from damage, install pieces of a rubber tube on the studs of the lower connecting rod head.

9. Using a hammer handle, push the piston up the cylinder block and remove it from the cylinder block.

10. Install the connecting rod cap on the lower head of the connecting rod and screw it with nuts, which will allow you to keep them as a set and not confuse them.