Attention! If your radio has an anti-theft code, check that you have the pairing codes before disconnecting the battery.

Attention! On models since 1993, the airbag system is disabled if the battery is disconnected for an extended period. If the airbag warning light comes on and stays on after reconnecting the battery, take it to a specialist workshop to restore the system to normal.

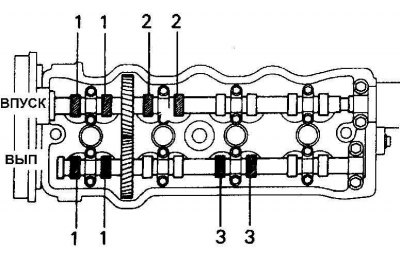

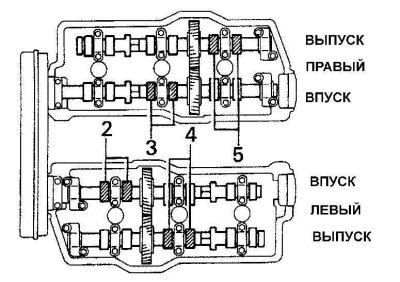

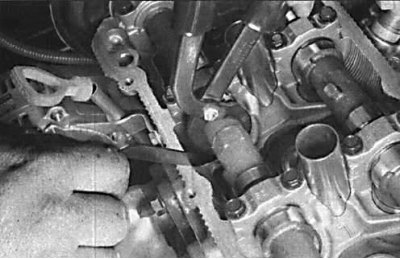

Pic. 1

On a four-cylinder engine, when the piston of the first cylinder is set to top dead center on the compression stroke, it is necessary to measure the clearance of the exhaust valves in cylinders No. 1 and No. 3 and the intake valves in cylinders No. 1 and No. 2.

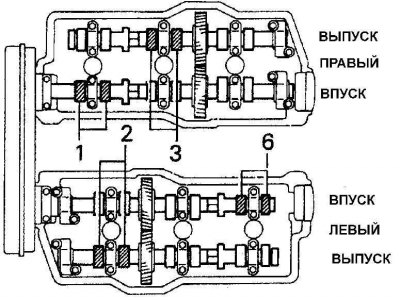

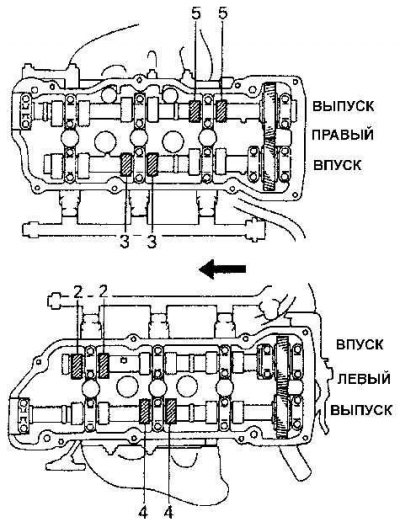

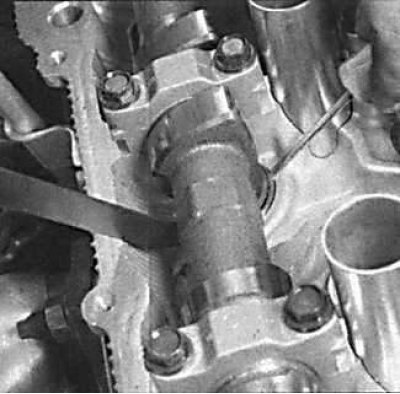

Pic. 2

On the 3VZ-FE engine, when the piston of the first cylinder is set to top dead center on the compression stroke, measure the clearance of the valves marked with numbers.

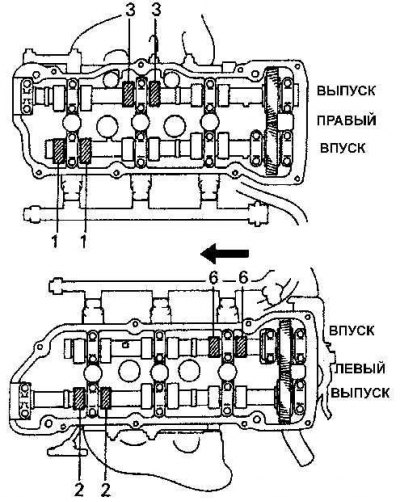

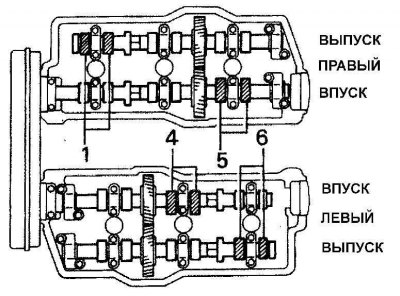

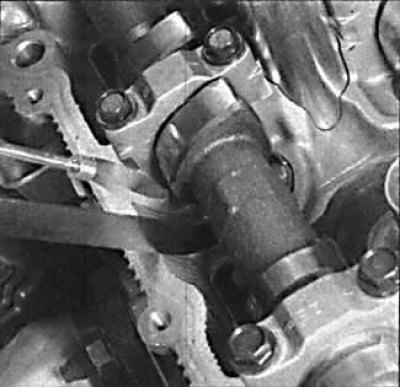

Pic. 3

On the 1MZ-FE V6 engine, when the piston of the first cylinder is set to top dead center on the compression stroke, check the clearance of the valves indicated by numbers.

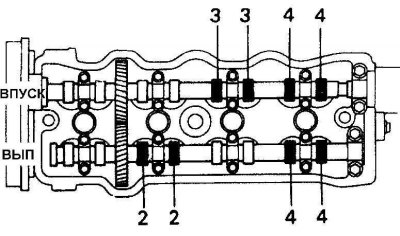

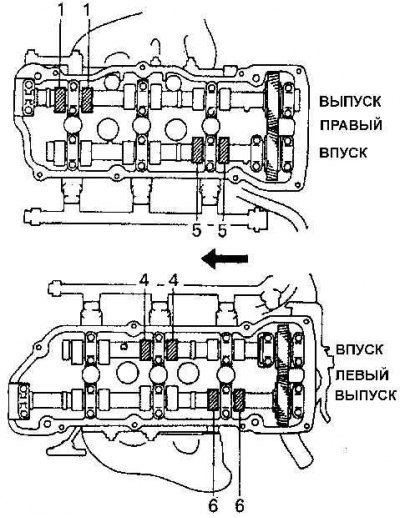

Pic. 4

On four-cylinder engines, rotate the crankshaft one full revolution, realign the timing marks, and check the valve clearances on the remaining cylinders.

Pic. 5

On the 3VZ-FE V6 engine, after turning the engine crankshaft 240°from the position of the top dead center of the first cylinder in the compression stroke, check the clearance of the valves indicated by numbers.

Pic. 6

On the 1 MZ-FE V6 engine, after turning the engine crankshaft 240°from the position of the top dead center of the first cylinder in the compression stroke, check the clearance of the valves indicated by numbers.

Pic. 7

On the 3VZ-FE V6 engine, turn the engine crankshaft an additional 240°and check the valve clearance on the remaining cylinders.

Pic. 8

On the 1 MZ-FE V6 engine, rotate the engine crankshaft an additional 240°and check the valve clearance on the remaining cylinders.

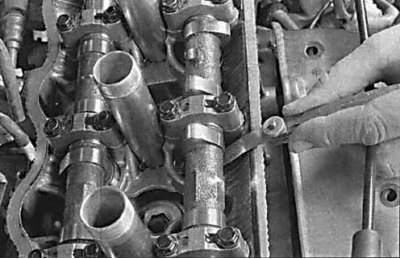

Using a special tool to push the valve lifter

Fixing the valve lifter in the pressed position

Removing the adjusting plate from the valve lifter

1. Remove the ground wire from the battery.

2. On a four-cylinder engine, disconnect the wires from the spark plugs.

3. On V6 engines, drain the coolant from the cooling system, remove the air filter housing and other items that prevent the removal of the cylinder head cover.

4. Using compressed air, remove dirt from the places where the candles are installed so that after unscrewing the candles it does not get into the cylinders. Unscrew the spark plugs.

5. Remove the cylinder head cover.

6. Set the number one piston to top dead center on the compression stroke.

7. Using a feeler gauge blade, measure the valve clearances and record them. (See figures 1-3) 8. On four-cylinder engines, turn the crankshaft one full turn and re-align the alignment marks. Check valve clearances on other cylinders (See fig. 4). On four-cylinder engines, when the piston of the fourth cylinder is at top dead center on the compression stroke, check the clearances of the exhaust valves of cylinders No. 2 and No. 4 and the clearances of the inlet valves of cylinders No. 3 and No. 4.

9. On V6 engines, turn the crankshaft 240°clockwise and check the valve clearance shown in fig. 5, 6. Next, turn the crankshaft another 240°and check the valve clearance on the remaining cylinders (See fig. 7).

10. After measuring the valve clearances, turn the engine crankshaft until the camshaft lobe above the valve to be adjusted is up.

11. Rotate the notch in the valve lifter towards the spark plug. Using the special tool, press the valve lifter down and lock the lifter in this position. Using tweezers or a magnet, remove the adjusting plate from the pusher (See figures Using a special tool to press the valve lifter, Locking the valve lifter in the depressed position, Removing the adjusting plate from the valve lifter).

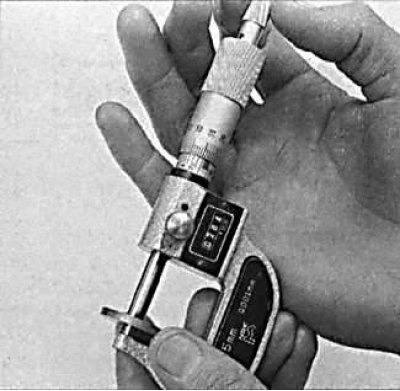

12. Measure the thickness of the adjusting plate with a micrometer. Use the following formula to determine the required shim thickness:

N = T + (A – V),

T is the thickness of the old adjusting plate,

A - valve clearance,

N is the thickness of the new adjusting plate,

V is the required valve clearance.

12. Select an adjusting plate whose thickness is closest to the calculated one. Adjustment plates are available in thicknesses from 2.500 to 3.300 mm in 0.05 mm increments.

13. Install a tappet tool with a long jaw around the bottom of the tappet and with a shorter lower jaw around the top of the tappet, press the tappet down by squeezing the tool handles and set the adjusting plate to the desired thickness. Remove the adjusting plate installer and measure the valve clearance.

14. Similarly, replace the shims on the valves that require adjustment.

15. Install spark plugs, cylinder head cover, high voltage wires and other previously removed items.

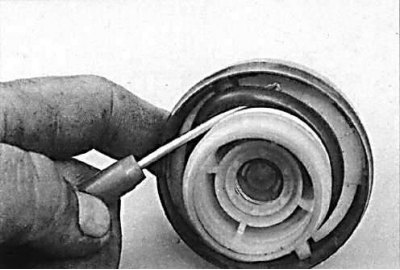

Replacing the Fuel Cap Gasket

1. Remove the fuel filler cap and, using a screwdriver, remove the old gasket from the groove in the cap.

2. Being careful, install a new gasket in the cover groove.

3. Reinstall the fuel filler cap.

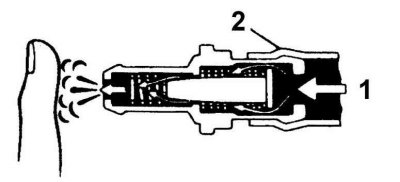

Checking the crankcase ventilation valve

The crankcase ventilation valve is located in the cylinder head cover.

1. Remove the hose from the valve and remove the crankcase ventilation valve from the cap, then reconnect the hose.

2. With the engine idling, place a finger on the crankcase ventilation valve and check for vacuum. If there is no vacuum, check the condition of the hose or valve.

3. Stop the engine and remove the crankcase ventilation valve from the hose. Blow out the valve from the side of the cylinder head. If air does not pass when the valve is bled, replace the valve.