Check on the engine

1. Check the operation of the fuel pump.

A) Turn on the ignition.

Note: do not start the engine.

b) Short the terminals with a jumper "+V" And "FP" diagnostic connector

V) Check for fuel pressure in the hose coming from the fuel filter.

Note: At this point, there is noise of fuel flowing from the fuel pressure regulator into the return line.

G) Remove the jumper from the diagnostic socket.

d) Switch off the ignition.

If there is no fuel pressure, check the following items:

- fusible inserts,

- circuit breakers,

- injection system main relay,

- fuel pump,

- start disable switch.

- wire connections

- electronic control unit.

2. Check fuel pressure.

A) Make sure the battery voltage is at least 11-12V.

b) Disconnect (-) battery wire.

V) Remove the bypass bolt, remove the two gaskets, and disconnect the fuel inlet hose from the fuel filter.

Note:

- Place a suitable container under the fuel filter;

- Slowly loosen the bypass bolt.

G) Drain fuel.

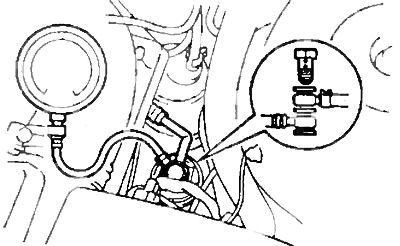

d) Using three new gaskets and an adapter fitting, connect a pressure gauge to the fuel line or fuel filter.

Tightening torque - 29 Nm

h) Wipe up spilled fuel.

And) Connect (-) wire to the battery.

To) Jumper the terminals "FP" And "+V" diagnostic socket.

l) Disconnect the vacuum hose from the fuel pressure regulator and plug it.

m) Measure fuel pressure at idle.

Nominal fuel pressure - 2.7-3.1 bar

n) Connect a vacuum hose to the fuel pressure regulator and measure the fuel pressure at idle.

Nominal fuel pressure - about 2.35 bar

If the fuel pressure differs sharply from the specified, check the vacuum hose and fuel pressure regulator.

o) Stop the engine and check that the fuel pressure remains at least 1.5 bar for 5 minutes after the engine has stopped. If not, check fuel pump, fuel pressure regulator and/or injectors.

P) After checking the fuel pressure, disconnect again (-) battery wire. Carefully remove the gauge, being careful not to splash fuel.

p) Using two new gaskets, reconnect the fuel inlet hose by tightening the bypass bolt.

Tightening torque - 29 Nm

Note: When installing the bypass bolt, hold the fuel line or fuel filter in place with a wrench.

With) Connect (-) wire to the battery.

T) Start the engine and check that there are no fuel leaks at the connections.

Fuel pump check

1. Disconnect the wire from the negative (-) battery terminals.

2. Remove the rear seat cushion.

3. Disconnect the fuel pump and fuel level sensor connectors.

4. Check the fuel pump.

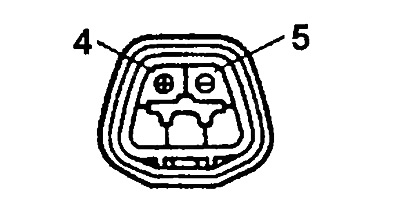

A) Check the electrical resistance of the fuel pump armature by connecting an ohmmeter to the terminals "4" And "5" fuel pump connector.

Resistance at 20°C - 0.2-3.0 ohm

If the resistance is not within the specified range, replace the fuel pump.

b) Check the operation of the pump by connecting (+) And (-) battery wires, respectively, to the terminals "4" And "5" pump connector. Make sure the fuel pump is working. Otherwise, replace the pump.

Note.

- To avoid burnout of the fuel pump winding, it must be checked quickly (within 10 seconds);

- Keep the fuel pump as far away from the battery as possible;

- Always turn on the pump only by connecting the wires to the battery terminals. Connect the connectors of the fuel pump and fuel level sensor;

- On the body of the fuel pump, the terminals are marked accordingly and Using the color of the wires, check the polarity of the battery connection.

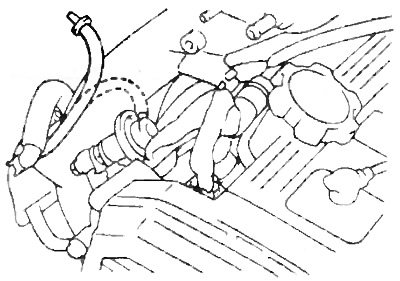

V) Check the pressure of the fuel pump, to do this, lower the pump (with filter on) into a bucket and pour about two liters of gasoline. Connect a manometer to the pump outlet pipe and connect the pump to the battery.

Observe the pressure gauge for 2 seconds, then turn off the pump.

- If the pump pressure is less than 3 bar, then it is defective and must be replaced.

- If the pressure is 3-4 bar, the pump is working, but will not last long.

- If the pressure is 4-5.5 bar and above, then the pump is working.

6. Install the rear seat cushion.

7. Connect the wire to the negative (-) battery terminal.

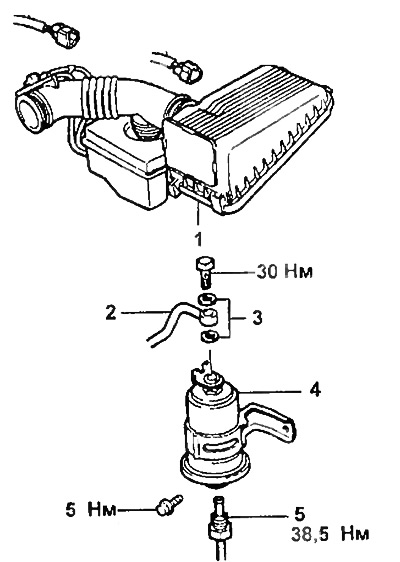

Removal and installation of the fuel filter

1. Remove the air filter cover with air duct (see below "Removing the throttle body").

Parts separated when dismantling the fuel filter.

1 - air filter cover,

2 - fuel hose,

3 - gaskets,

4 - fuel filter,

5 - fuel supply pipe.

1. Remove the air filter cover with air duct (see below "Removing the throttle body").

2. Disconnect the fuel outlet hose by unscrewing the bypass bolt.

- Tightening torque - 30 Nm

3. Turn away a tube of a supply of fuel.

- Tightening torque - 39 Nm

4. Remove the fuel filter by unscrewing the 2 fastening screws.

- Tightening torque - 5 Nm

The fuel filter is installed in the reverse order of its removal.

Removal and installation of the fuel pump

1. Disconnect the wire from the negative (-) battery terminals.

2. Remove the rear seat cushion.

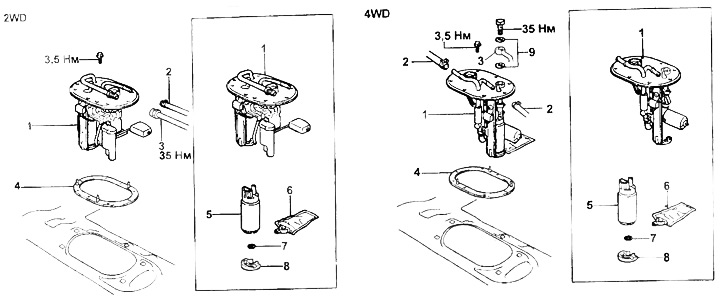

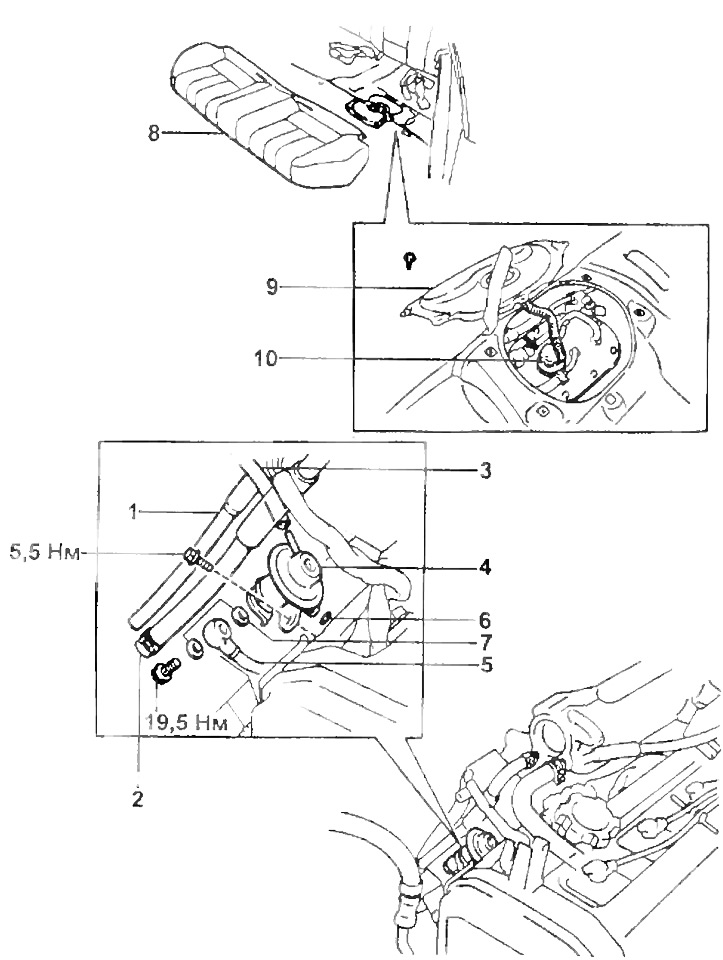

Parts separated when dismantling the fuel pump.

1 - pump bracket,

2 - fuel return pipe,

3 - fuel outlet pipe,

4 - gasket,

5 - fuel pump,

6 - pump filter,

7 - collar,

8 - rubber shock absorber,

9 - gasket.

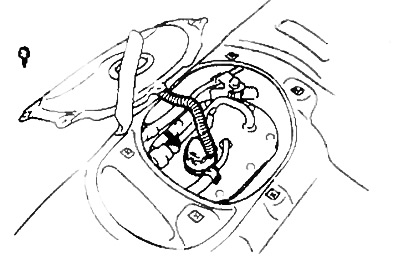

3. Remove the service hatch cover.

4. Remove the fuel pump and fuel gauge sensor assembly.

A) Disconnect the fuel pump and fuel gauge sensor connector.

b) Disconnect the fuel outlet and return pipes.

2WD Models

4WD Models

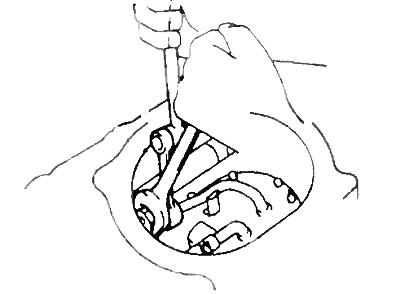

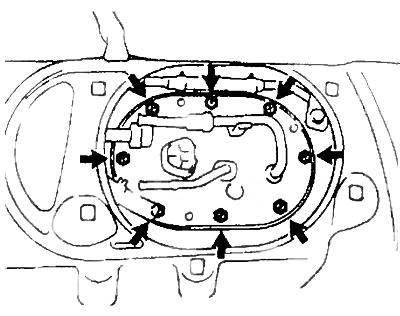

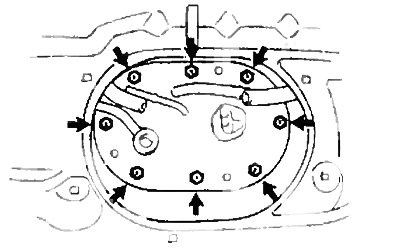

5. Disconnect the fuel pump mounting bracket from the fuel tank by unscrewing 8 bolts

- Tightening torque - 3.5 Nm

2WD Models

4WD Models

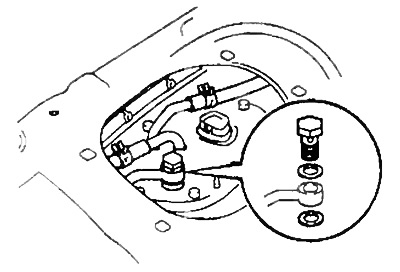

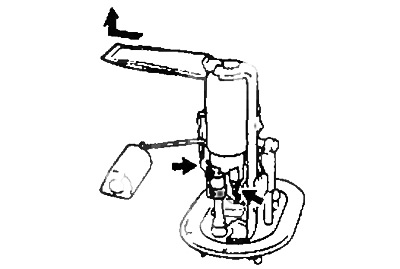

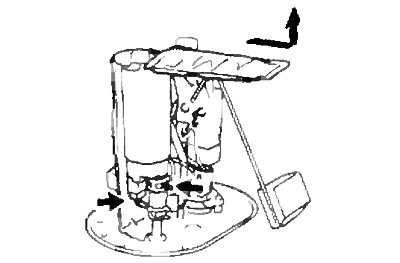

6. Remove the pump from the bracket.

2WD Models

4WD Models

Parts removed when dismantling the fuel pressure regulator.

1 - hose system for increasing the idle speed when the air conditioner is turned on,

2 - power steering hose,

3 - vacuum hose,

4 - fuel pressure regulator,

5 - fuel pipe No. 2,

6 - ring seal,

7 - gasket,

8 - rear seat cushion,

9 - service hatch cover,

10 - pump connector.

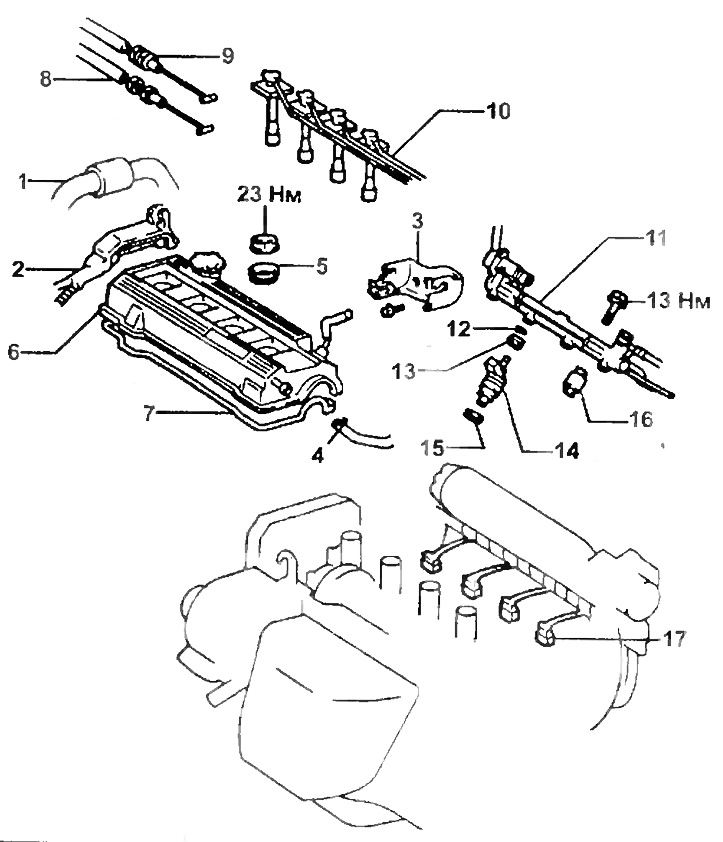

Parts removed when dismantling the injectors.

1 - power steering hose

2 - wiring protection,

3 - bracket,

4 - hose of the crankcase ventilation system,

5 - seal,

6 - cylinder head cover,

7 - gasket,

8 - accelerator cable,

9 - throttle actuator cable (from automatic transmission),

10 - high voltage wires,

11 - fuel manifold,

12 - ring seal,

13 - fuel manifold mounting bolt,

14 - nozzles,

15 - safety sleeve,

16 - spacer,

17 - injector connectors.

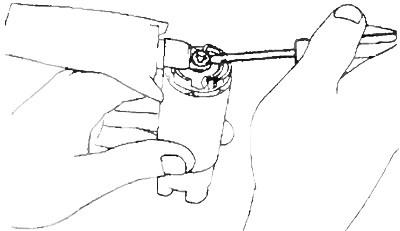

6. Using a small screwdriver, remove the clamp, and then pull out the filter.

Note. The fuel pump is installed in the reverse order of its removal.