Rotor check

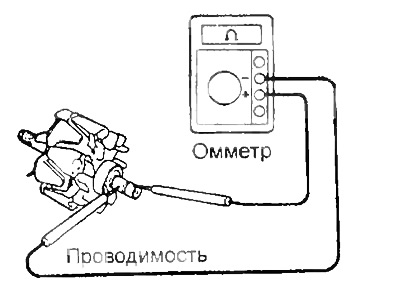

1. Check for an open in the field winding.

Use an ohmmeter to measure the resistance between the slip rings.

- Rated resistance (cold) - 2.8-3.0 ohms

If the resistance tends to infinity, i.e. circuit is open, replace the rotor.

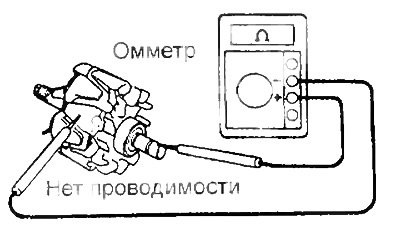

2. Check if the excitation winding is shorted to "mass".

Using an ohmmeter, measure the resistance between the rotor pole and the slip ring.

If there is no resistance (circuit is closed), then replace the rotor.

3. Check slip rings.

A) Check the working surfaces of the slip rings. They should not have scuffs or chips.

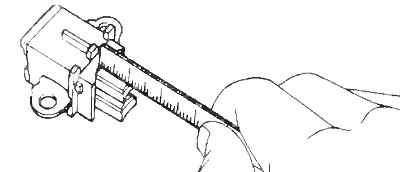

b) Using a caliper, measure the diameter of the slip rings.

- Nominal diameter - 14.2-14.4 mm

- Minimum allowable - 12.8 mm

If the diameter of the slip rings is less than the minimum allowable, then replace the rotor.

Stator check

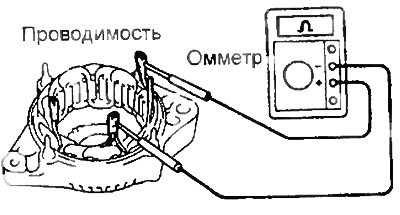

1. Check for an open in the stator winding.

Using an ohmmeter, check for continuity between the terminals of the stator winding coils.

Otherwise, replace the stator.

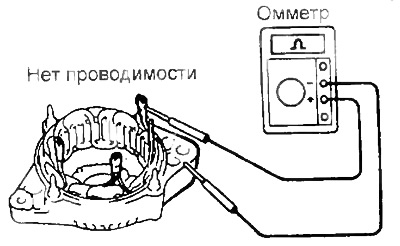

2. Check if the stator winding is shorted to "mass".

Using an ohmmeter, verify that there is no continuity between the stator housing and the stator coil leads.

Otherwise, replace the stator.

Checking the brushes

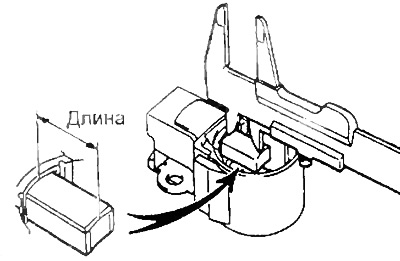

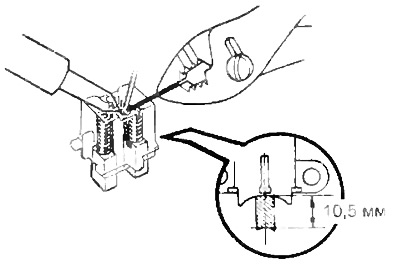

1. Measure the length of the protruding part of the brushes.

- Nominal - 10.5 mm

- Minimum allowable - 1.5 mm

Type A

Type B

If the length of the protruding part of the brush is less than the minimum allowable, replace the brushes (usually type A) or brush holder assembly (type B).

2. Replacement of brushes (if necessary)

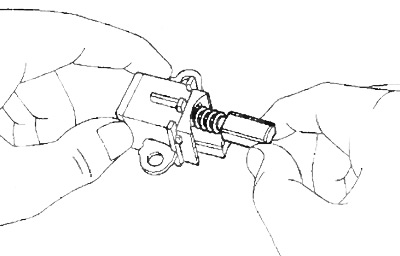

A) Unsolder the brush wire from the brush holder lead and remove the brush and brush spring.

b) Pass the wire through the hole in the brush holder and insert the brush into the brush holder.

V) Solder the brush wire to the brush holder lead so that the protruding length of the brush matches the nominal value given above.

G) Make sure the brushes move freely without binding.

d) Cut off the rest of the wire.

e) Apply insulating paint to the solder points.

Checking the rectifier unit

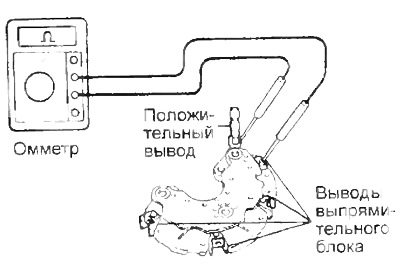

1. Checking the positive valve.

A) Connect the negative probe of an ohmmeter to the positive terminal of the rectifier unit, and connect the positive probe in series to each of the other three terminals.

Check for conductivity in all three measurements.

b) Reverse the polarity of the tester probes and repeat the procedure of step a). Verify that there is no conduction on all three measurements. If the conditions are not met, replace the rectifier unit.

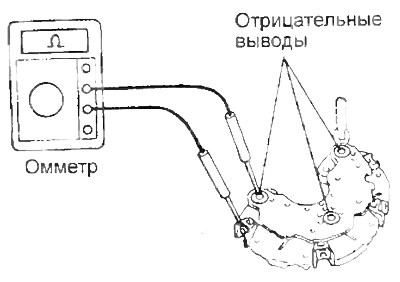

2. Checking the negative valve.

A) Connect the positive probe of the ohmmeter to the negative terminal of the rectifier unit, and connect the negative probe in series to each of the other terminals. Check for conductivity in all three measurements.

b) Reverse the polarity of the tester probes and repeat the procedure of step a). Verify that there is no conduction on all three measurements. If the conditions are not met, replace the rectifier unit.

Bearing check

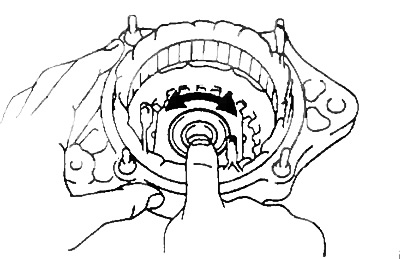

1. Checking the front bearing. Check that the front bearing runs smoothly without binding.

2. Replace the bearing if necessary.

A) Loosen the 4 screws and remove the bearing holder.

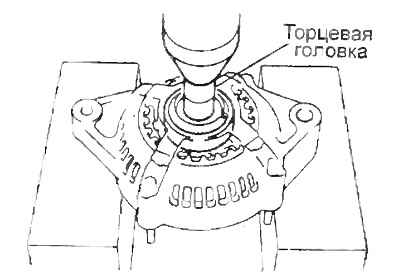

b) Press out the front bearing using a press and an appropriately sized socket.

V) Using a special punch and a press, press the new front bearing into the drive side alternator cover.

G) Install the bearing holder and tighten the 4 screws securing it.

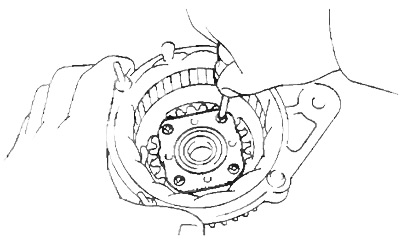

3. Checking the rear bearing. Check that the rear bearing runs smoothly without binding.

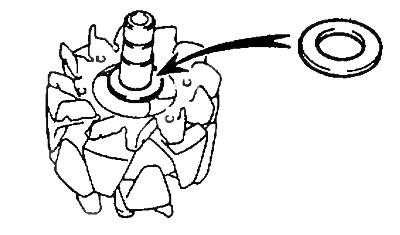

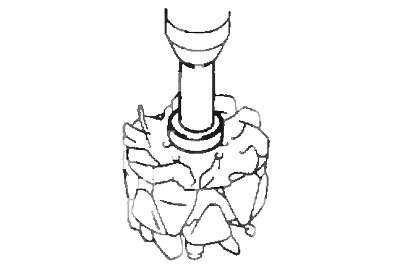

4. If necessary, replace the rear bearing.

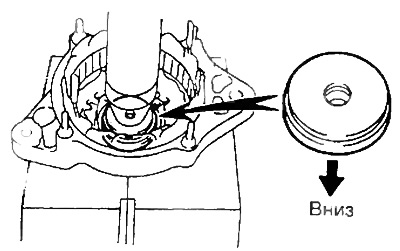

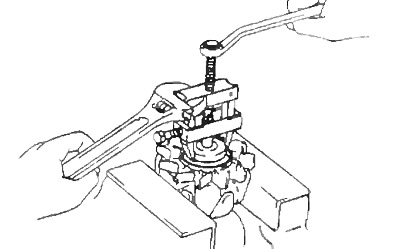

A) Using a puller, remove the outer bearing cap and rear bearing.

Note: be careful not to damage the rotor.

b) Remove the inner bearing cover.

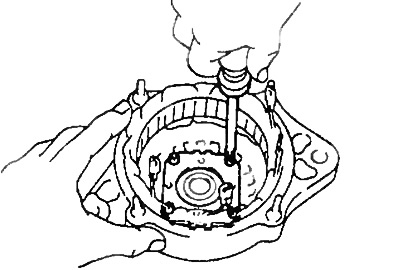

V) Install the inner bearing cap onto the rotor.

b) Using a press and drift, install the new rear bearing onto the rotor shaft.

V) Install the outer bearing cover.