Replacement of brake pads

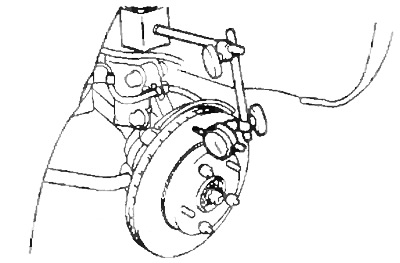

1. Remove the front wheel and temporarily secure the brake disc with wheel nuts.

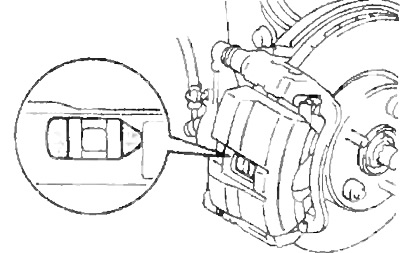

2. Through the control hole in the caliper, check the thickness of the brake pads.

- Minimum thickness - 1.0 mm

Replace pads if necessary.

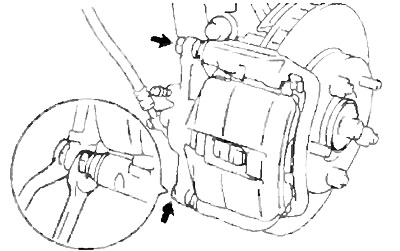

3. Holding guide fingers, turn away bolts and remove a support.

Note: Do not disconnect the brake hose from the caliper. Secure the caliper with wire to the rack, do not leave it hanging on the brake hose.

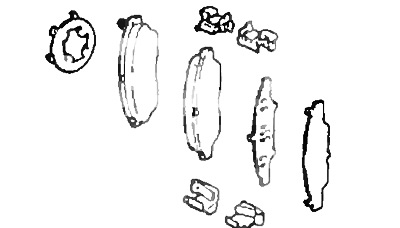

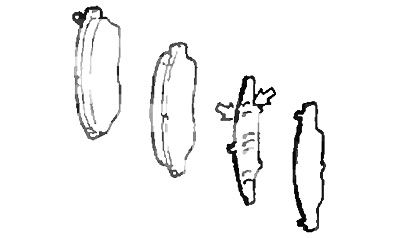

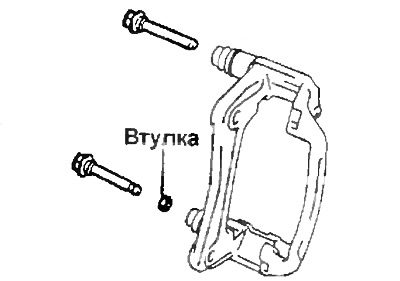

4. Remove the parts shown in the figure.

5. Check disc thickness and runout (see below).

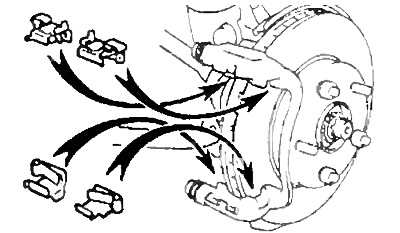

6. Install the four retaining plate bushings.

7. Install new pads.

Note: if you need to replace at least one brake pad, then replace all of them to ensure uniform braking. When replacing the pads, the anti-squeak pads also change.

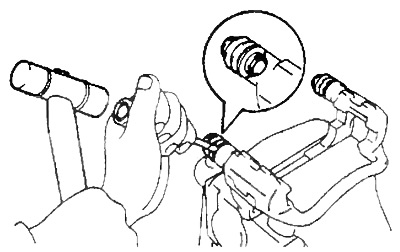

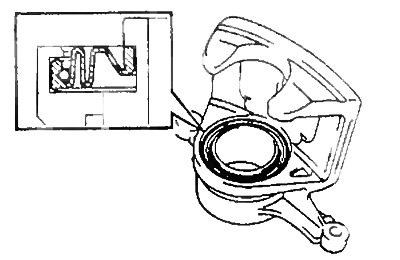

A) Apply special disc brake grease to both sides of the inner anti-squeak pad.

b) Install anti-squeak pads on each pad as shown.

V) Install the brake pads.

Caution: Do not allow oil or grease to come into contact with the running surfaces of the pads and disc.

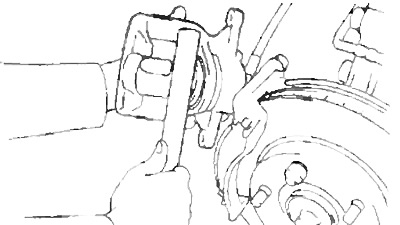

8. Install the caliper.

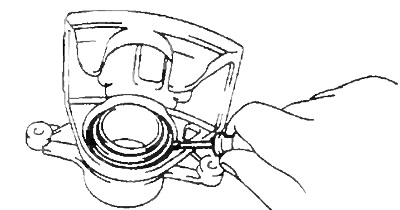

A) Remove a small amount of brake fluid from the reservoir.

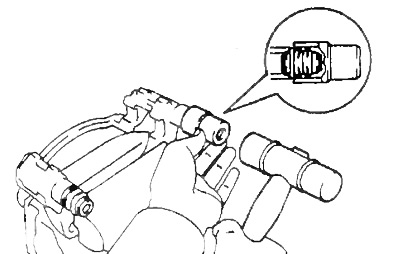

b) Push the piston into the cylinder using the hammer handle.

Note: If the piston does not move well, loosen the bleeder screw and retract the piston if there is a slight leakage of brake fluid.

V) Install the support.

G) While holding the guide pins, tighten the bolts.

- Tightening torque - 35 Nm

9. Install the front wheel.

- Tightening torque - 105 Nm

10. Check the brake fluid level in the reservoir and top up if necessary.

Removing the caliper

1. Disconnect the brake hose.

A) Turn away a nipple bolt, remove two linings and disconnect a brake hose.

b) Using a suitable container, drain the brake fluid.

2. Remove the caliper.

A) While holding the guide pins, loosen the mounting bolts.

b) Turn away bolts of fastening.

V) Remove the caliper from the bracket.

3. Remove the brake pads.

4. Turn away bolts of fastening and remove a support bracket.

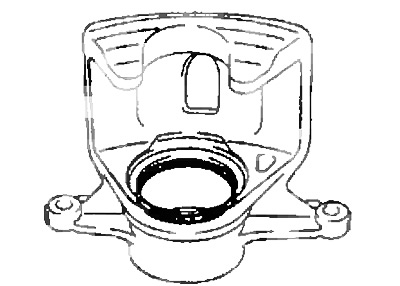

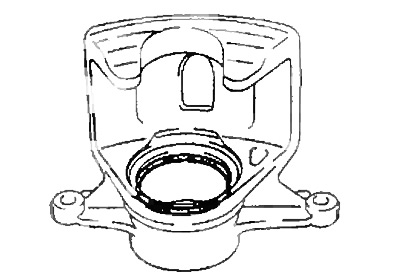

Caliper disassembly

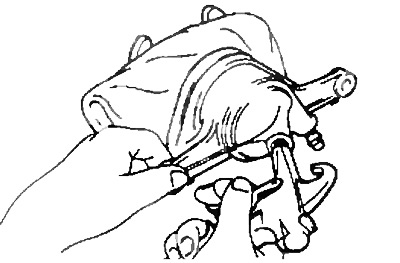

1. Using a screwdriver, remove the brake cylinder boot spring ring and boot.

2. Remove the piston.

A) Place a rag between piston and cylinder.

b) Using compressed air, remove the piston from the cylinder.

Caution: Do not place your fingers in front of the piston when using compressed air.

3. Using a screwdriver, remove the cuff.

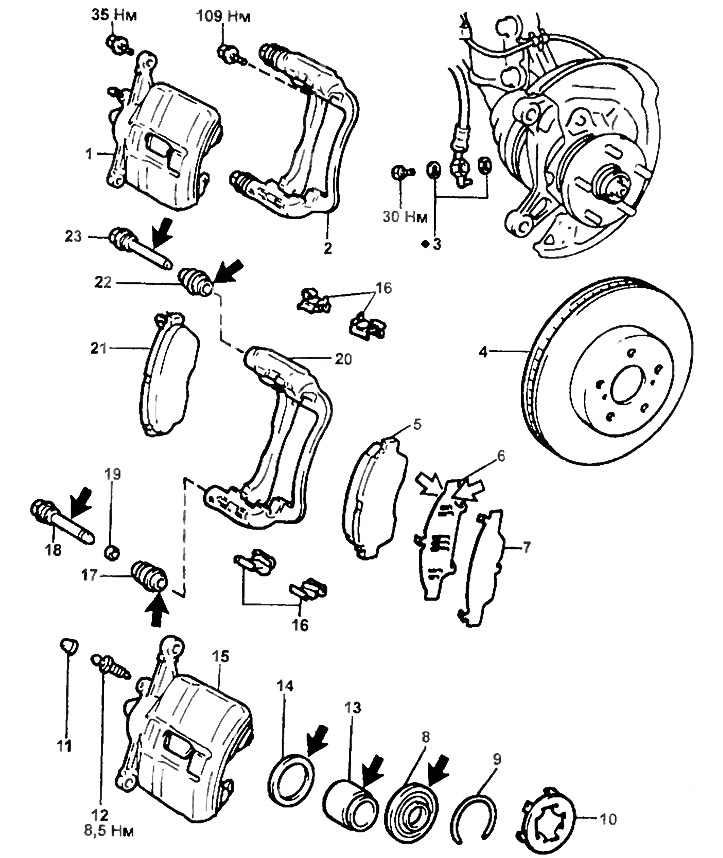

Front brakes.

1 - caliper assembly,

2 - caliper bracket,

3 - gasket,

4 - brake disc,

5 - outer brake shoe,

6 - internal anti-creak gasket,

7 - anti-creak gasket,

8 - cover,

9 - spring ring,

10 - anti-creak gasket,

11 - cap,

12 - bleed valve,

13 - piston,

14 - cuff,

15 - support,

16 - retaining plate insert,

17, 22 - dust cover,

18, 23 - guide pin,

19 - bushing,

20 - caliper bracket,

21 - internal brake shoe.

4. Remove guide pins and dust covers.

A) Remove two guide pins.

b) Using a screwdriver and hammer, remove the dust covers.

Checking and repairing the front brakes

1. Measure the thickness of the brake pads.

- Nominal thickness - 12.0 mm

- Minimum thickness - 1.0 mm

Replace the pads if the pad thickness is less than minimum or if the pads are unevenly worn.

2. Measure the runout of the brake disc at a distance of 10 mm from the outer edge. The maximum allowable runout is 0.05 mm

If the brake disc runout is greater than or equal to the maximum value, check the bearing axial clearance and hub runout.

3. Using a caliper, measure the thickness of the brake disc.

- Nominal thickness - 25 mm

- Minimum thickness - 23 mm

Replace the disc if the disc thickness is less than the minimum allowable.

4. Adjust disc runout if necessary.

A) Loosen the wheel nuts and remove the disc.

b) Reinstall the disc by turning it ⅕ of a turn from its original position on the hub, and measure the runout of the disc in all installations. Choose the minimum value from those received. Compare it with the maximum allowed.

V) If the value obtained is less, then install the disk in this position.

G) If the value obtained is greater, then replace the disk, and repeat the steps "b" And "V").

Caliper Assembly

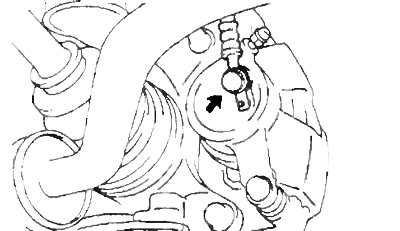

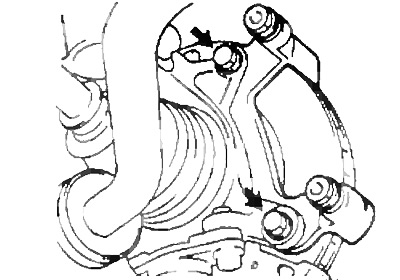

1. Lubricate the surfaces indicated by the arrows in the assembly drawing.

2. Install dust covers and guide pins.

A) Using a suitable mandrel and a hammer, install two new dust covers.

b) Make sure the dust covers fit snugly into the grooves of the caliper bracket.

V) Insert two guide pins into the caliper bracket.

Attention: when assembling, please note that the sleeve is installed with the lower guide pin.

G) Install the caliper bracket and tighten the mounting bolts.

- Tightening torque - 109 Nm

3. Install the cuff.

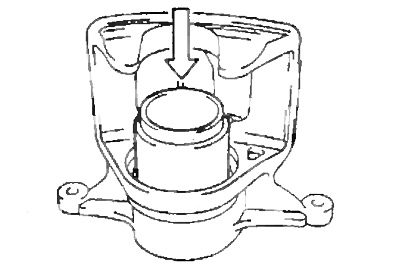

3. Install the piston in the cylinder.

4. Install the cylinder boot and circlip.

Caliper installation

1. Install the brake pads.

2. Install the caliper.

A) Install the caliper onto the bracket.

b) While holding the guide pins, tighten the two mounting bolts

- Tightening torque - 35 Nm

3. Connect the brake hose.

Install the brake hose with two new gaskets.

- Tightening torque - 30 Nm

4. Fill the reservoir with brake fluid and bleed the brake system.

5. Check for leaks.

6. Install the front wheel.

- Tightening torque - 105 Nm

7. Check the tension of the front brake cable.